Safety Features in Hot Cold Chambers: Ensuring Reliable and Secure Operation

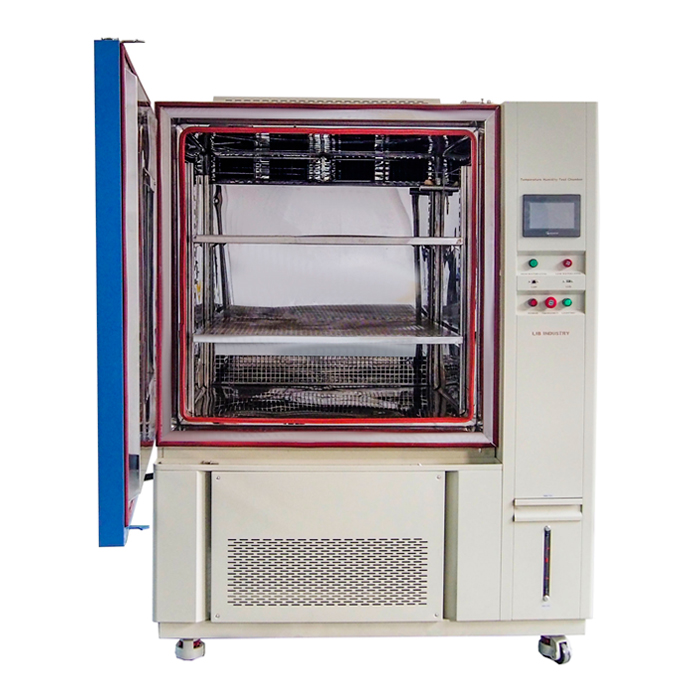

Hot cold chambers are essential tools in various industries, enabling manufacturers to simulate extreme temperature conditions to test the durability of their products. Whether testing electronics, automotive components, or aerospace materials, safety in a hot cold chamber is paramount.

Over-Temperature Protection Systems: Safeguarding Against Thermal Runaway

One of the most critical safety features in hot cold chambers is the over-temperature protection system. During extreme temperature tests, thermal runaway can occur if internal temperatures rise uncontrollably. This phenomenon can damage the chamber, the products being tested, and even pose a danger to operators.

Hot cold chambers are equipped with temperature sensors that continuously monitor the internal conditions. When temperatures exceed safe thresholds, the system automatically triggers cooling mechanisms or shuts down the chamber to prevent overheating. This rapid response ensures both the equipment and personnel are safeguarded from thermal risks. For example, in automotive testing, where components are exposed to high temperatures, over-temperature protection ensures that tests are conducted without compromising the integrity of the equipment or risking thermal accidents.

Refrigerant Safety: Handling Hazardous Substances with Care

Refrigerants play a crucial role in hot cold chambers, especially during cooling cycles. However, many refrigerants can be hazardous if not handled properly. Leaks or improper handling can lead to health risks, environmental damage, or even fires in extreme cases.

Modern hot cold chambers incorporate several refrigerant safety mechanisms. These include leak detection systems that alert operators to any breach in the refrigerant circuit, preventing exposure to harmful gases. Additionally, refrigerant management systems ensure that gases are contained and processed safely, minimizing the risk of contamination or environmental harm. For instance, in laboratories or industrial environments where refrigerants such as R-404A are used, these safety protocols help maintain a secure working environment, ensuring compliance with global environmental regulations.

Electrical Safety Mechanisms: Protecting Users from Shock and Short Circuits

Given the complexity of hot cold chambers, electrical safety is another critical consideration. These chambers rely on powerful electrical systems to regulate temperature, control humidity, and perform tests. Without robust electrical safety mechanisms, there's a risk of short circuits, electrical shocks, or even fires.

To mitigate these risks, hot cold chambers are designed with protective insulation, circuit breakers, and grounding systems. These mechanisms safeguard users from accidental contact with live wires or electrical surges. For example, advanced chambers feature overload protection, which automatically cuts off the electrical supply when abnormal voltage or current levels are detected. This ensures that both the equipment and operators remain protected, reducing the likelihood of electrical malfunctions or injuries during testing.

Emergency Stop Functionality: Rapid Shutdown Capabilities for Unforeseen Events

In any testing environment, emergencies can arise unexpectedly. Whether it's a sudden equipment failure, human error, or an external hazard, having a rapid shutdown mechanism is essential. The emergency stop functionality in hot cold chambers allows operators to immediately halt all operations in the event of a crisis.

This feature is designed for ease of access, with emergency stop buttons placed strategically around the chamber. When pressed, the system instantly powers down the chamber, stopping temperature fluctuations and halting any ongoing tests. For example, during pharmaceutical testing, where sensitive materials are being exposed to extreme conditions, the ability to swiftly stop the chamber can prevent costly damage to both the products and the equipment. Emergency stop capabilities ensure that any unforeseen issues are managed quickly and effectively, safeguarding the testing process from potential hazards.

Door Safety Interlocks: Preventing Accidental Exposure to Test Environments

Door safety interlocks are another crucial feature of hot cold chambers. These interlocks prevent the chamber door from opening while tests are in progress, thus protecting operators from exposure to extreme temperatures. If a chamber is running at -40 °C or 180 °C, accidental exposure can lead to severe burns or frostbite.

Hot cold chambers are equipped with sensor-based door interlock systems that automatically lock the door until the internal environment is safe for entry. For example, in aerospace testing, where materials are subjected to high heat, these safety interlocks ensure that the chamber remains sealed until temperatures return to safe levels. This feature not only protects operators but also prevents test samples from being compromised by premature exposure to external conditions.

At LIB Industry, we specialize in designing and producing top-tier hot cold chambers with advanced safety features. Interested in learning more? Contact us today at ellen@lib-industry.com for more information on how we can meet your testing needs.

References

1. "Safety Considerations in Environmental Test Chambers," Journal of Testing and Evaluation, 2022.

2. "Refrigerant Safety in Industrial Applications," International Journal of Refrigeration, 2021.

3. "Electrical Safety in Environmental Testing Equipment," IEEE Transactions on Industrial Electronics, 2023.

4. "Emergency Stop Mechanisms in Laboratory Equipment," Safety Science, 2023.

.jpg)