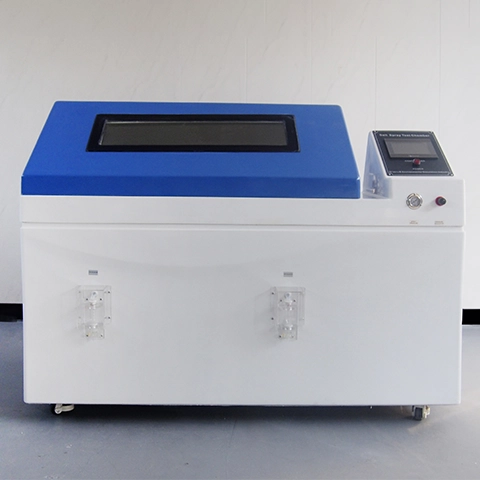

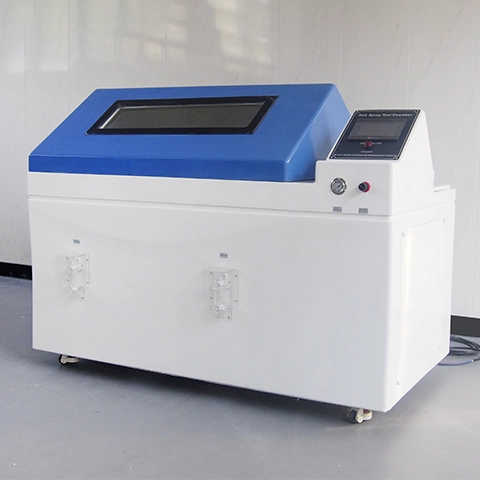

Astm B117 Chamber

Temperature Range:+10 ℃ ~ +90 ℃

Humidity Range:30% ~ 98% RH

Humidity Deviation:+2%, -3%

Salt Fog Deposition:1~2ml / 80cm2 · h

Cooling system Mechanical compression refrigeration system

Refrigerant:R404A(replaceable)

- Product Description

Astm B117 Chamber Manufacturer & Supplier

LIB industry is professional astm B117 chamber manufacturers and suppliers in China, to buy or wholesale from our factory. For quotation, contact us now.

The astm b117 chambers from LIB Industries is a corrosion testing equipment designed to simulate salt spray conditions for evaluating the corrosion resistance of materials and surface finishes. It fully complies with international standards such as ASTM B117, ISO 9227, and more.

The LIB Industries ASTM B117 salt spray chamber features a spacious corrosion testing area with adjustable shelves to accommodate different-sized test specimens. The chamber walls are made of corrosion-resistant glass fiber reinforced plastics. The chamber includes spray towers, salt solution tank, spray nozzle, salt fog collecter, and other components required to create a continuous salt fog environment.

Standards Compliance

The LIB Industries astm b117 test chamber is designed to meet the following standards:

ASTM B117 - Operating salt spray (fog) apparatus

ISO 9227 - Corrosion tests in artificial atmospheres

IEC60068-2-52 Corrosion tests in artificial atmospheres

ASTM G85 - Corrosion testing

Technical Specifications

Model | S-150 | S-250 | S-750 | S-010 | S-016 | S-020 |

Internal dimensions (mm) | 590*470*400 | 1000*640*500 | 1100*750*500 | 1000*1300*600 | 900*1600*720 | 1000*2000*800 |

Overall dimensions (mm) | 1460*760*1140 | 1850*960*1350 | 1950*1030*1350 | 2000×1300×1600 | 2300×1300×1700 | 2700×1300×1900 |

Interior Volume (L) | 110 | 320 | 410 | 780 | 1030 | 1600 |

Temperature Range | Ambient ~ +60 ℃ | |||||

Temperature Fluctuation | ± 0.5 ℃ | |||||

Temperature Deviation | ± 2.0 ℃ | |||||

Humidity Range | 95% ~ 98% RH | |||||

Salt Fog Deposition | 1~2ml / 80cm2 · h | |||||

Spray Type | Continuous / Periodic | |||||

Salt Fog Collected | Fog collector and fog measure cylinder | |||||

Air Preheating | Saturated air barrel | |||||

Spraying System | Atomizer tower and Spray nozzles | |||||

Controller | PID controller | |||||

Safety Device | Humidifier Dry-combustion Protection; Over-temperature Protection; Over-current Protection; Water Shortage Protection; Earth leakage Protection | |||||

Material | Glass fiber reinforced plastics | |||||

Standard Configuration | 6 round bars and 5 V-shaped grooves | |||||

Product Details

|

|

|

| Salt Water Tank Built-in salt solution tank and external salt water tank Brine mixing system to keep the salt solution even | Controller PID control system Network connection computer English/French/Spanish/German/Russian | Salt The salt is used for salt spray corrosion test The purity of the salt is 99.5% |

|

|

Key Advantages

●Automatic Water Intake Function: The astm B117 chamber includes an automatic water intake system to maintain consistent salt solution levels.

●Quartz Nozzle : Quartz nozzles provide excellent corrosion resistance and produce a finer, more uniform salt fog mist.

●Glass fiber reinforced plastics: The chamber body is made of glass fiber reinforced plastics, offers excellent corrosion resistance even under constant salt

spray conditions. This ensures a long working life for the chamber.

●Precise temperature and humidity control: Temperature, humidity and salt fog controlled

●Optional accessories available: spray nozzle, fog collecter, salt, air compressor

Applications:

The astm B117 chamber is ideal for corrosion testing of:

Metals and alloys

Paints, coatings and finishes

Electronics and electrical components

Automotive parts

Aerospace and defense components

FAQ:

What solutions can be used for salt spray testing?

The most common solution is 5% sodium chloride as per ASTM B117. Other solutions like acetic acid salt spray, copper-accelerated acetic acid salt spray (CASS) can also be used.

What maintenance is required?

Regular cleaning of spray nozzles, towers, reservoirs is needed. Salt deposits on chambers walls should also be cleaned. Solution filters need replacement periodically.

What accessories are available?

We offer a range of accessories like additional spray collecter, specimen holders , salt, spray nozzle