Thermal Shock Test Chamber

Lower limit Temperature:-75℃

Upper limit Temperature:+220℃

Temperature Range:-70℃~+220 ℃

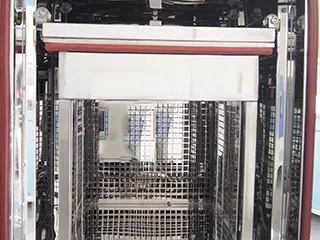

The specimen is automatically transferred from the cold chamber to the hot chamber by basket.

Temperature Recovery Time: Within 5 minutes

Refrigerant: Environmental refrigerant

- Product Description

Thermal Shock Test Chamber Manufacturer & Supplier

LIB industry's Thermal Shock Test Chamber can perfrom thermal shock testing from -70 to +200°C.The specimen automatic transferred from cold chamber to hot chamber by basket. During the test, the sample is rapidly transferred between the hot and cold compartments, creating thermal stress.

Thermal shock test chambers are equipped with precise temperature control systems to achieve the desired temperature ranges and transition times.

Technical Specifications

Model | TS-162 | TS-340 | TS-500 | TS-1000 |

Internal Dimensions (mm) | 300*300*250 | 450*450*360 | 650*650*500 | 850*850*700 |

Overall Dimension (mm) | 1560*870*1545 | 1710*1020*1845 | 1910*1220*2265 | 2110*1420*2665 |

Interior Volume (mm) | 22L | 72L | 211L | 505L |

Loading Capacity | 20kg | 30kg | 50kg | 60kg |

Upper limit Temperature | +220℃ | |||

Heating Time | Ambient ~ + 200℃, within 30 minutes | |||

Lower limit Temperature | -75℃ | |||

Cooling time | Ambient ~ -70℃, within 30 minutes | |||

High Temperature Exposure Range | Ambient +20 ~ +200°C | |||

Low temperature Exposure Range | –65 ~ -5°C | |||

Temperature Fluctuation | ≤±0.5℃ | |||

Temperature Deviation | ≤±3 ℃ | |||

Temperature Recovery Time | Within 5 minutes | |||

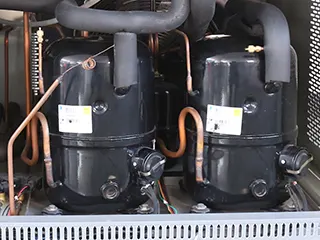

Cooling System | Mechanical compression refrigeration system | |||

Controller | Programmable color LCD touch screen controller, Ethernet connection | |||

Safety Device | Over-temperature protection, Over-current protection; Refrigerant high-pressure protection; Earth leakage protection | |||

Exterior Material | Steel Plate with protective coating | |||

Interior Material | SUS304 stainless steel | |||

Observation Window | Interior lighting, double-layer thermo stability silicone rubber sealing | |||

Standard Configuration | 2 shelves | |||

Product Details

|

|

|

| Cooling system Mechanical compression refrigeration system French TECUMSEH compressor Environmentally friendly refrigerant | Cable hole The standard inner hole diameter is 50mm/100mm/200mm Located on the basket | Basket The specimen automatic transferred from cold chamber to hot chamber by basket. The basket slides vertically and smoothly through rail |

|

|

Thermal Shock Test Chamber Key Features

◇Precision Control: Maintain accurate temperature profiles.

◇Reliability: Sturdy construction for prolonged usage.

◇User-Friendly: Intuitive interface for easy operation.

◇Versatility: Supports a wide range of testing standards.

◇Efficiency: Fast transition times for accelerated testing.

Application

Thermal Shock Test Chamber is ideal for aerospace, automotive, electronics, and material science industries, assessing products' reliability in diverse environments.

FAQ

What is a thermal shock chamber and how does it work?

These chambers rapidly change temperature by physically moving the product from a hot zone to a cold zone, or rapidly changing the air temperature by specialized means.

What are the different models of thermal shock chambers available from LIB?

There are elevator/lift types and air-exchange damper types.

What temperature ranges can LIB Thermal Shock Test Chamber achieve?

All are around -65 to 180°C in range

How do thermal shock chambers simulate extreme environmental conditions?

Subfreezing temperatures are by a cascade refrigeration,

Hot temperatures are generated by electrical resistance heaters.

What safety features are included in LIB thermal shock chambers?

Elevator systems have special protections to avoid injury from moving lift.

How do LIB thermal shock chambers compare in terms of energy efficiency?

The modern TSA series are 50 to 70% more efficient than their predecessors.

.webq.jpg)