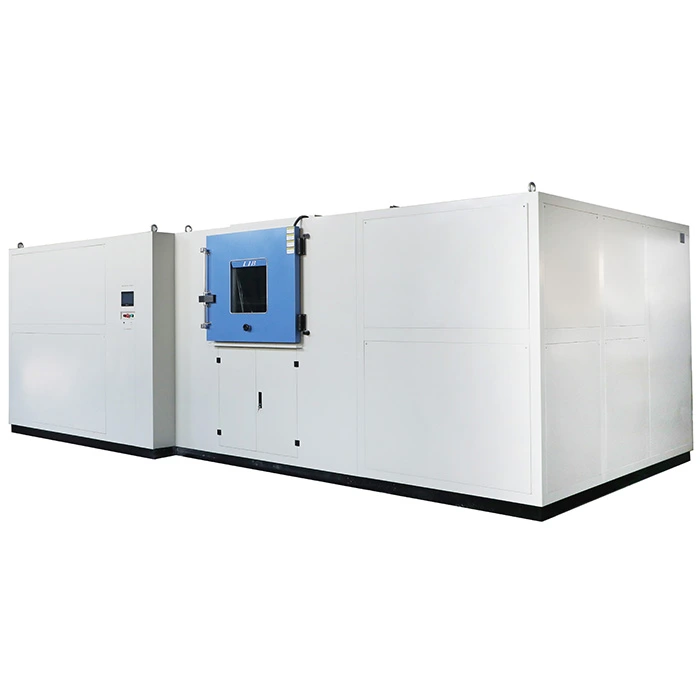

Mil std 810d Test Chamber

Name:blowing sand and dust test chamber

Model:DI-1000

Capacity:800L/1000L/1500L/2000L and more

Temperature Range:Ambient ~ +50℃

Humidity Range:< 30% RH

Normal Wire Diameter:50um

- Product Description

LIB's Mil std 810d Test Chamber

The LIB industry's Mil std 810d Test Chamber is designed to simulate and test the effects of sand and dust environments on materials, components, and systems according to military standards such as MIL-STD-810. With rugged stainless steel construction, programmable test parameters, and sand circulation, this chamber provides reliable and repeatable sand and dust testing capabilities.

It features a stainless steel interior and reinforced door seal to withstand abrasive test conditions. The insulated chamber provides stable thermal conditions from ambient to +80°C. The air circulation system includes a high-powered blower and cyclone generators to maintain uniform sand density and velocity throughout the test space. The programmable PLC control allows custom test profile creation with real-time monitoring on a color touchscreen.

Standards

MIL-STD-810

IEC 60068-2-68

Specifications

Model | DIM-1000 |

Internal Dimension | 1000*1000*1000mm D*W*H |

Overall Dimension | 3000*6100*2200mm D*W*H |

Interior Volume | 1000L |

Blowing Dust | |

Air velocity | 1.5 -8.9m/s |

Concentration of dust | 10.7±7g/ m³ |

Dust particles | < 150μm |

Blowing sand | |

Air velocity | 18.0 -29.0m/s |

Concentration of sand | 0.18+0.2g/m³; 1.1+0.3g/m³; 2.2+0.5g/m³ |

Sand particles | 149μm - 600μm, 600μm - 850μm |

Controller | Programmable color LCD touch screen controller, Ethernet connection |

Testing Platform Diameter | 600mm |

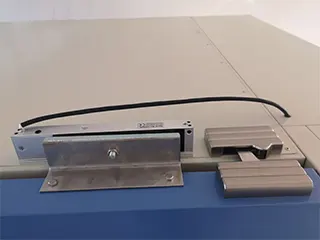

Door Lock | Electromagnetic lock |

Testing Platform Speed | 1-7 r.p.m |

Dust Detector | Integrated dust detector |

Exterior Material | A3 Steel Plate with protective coating |

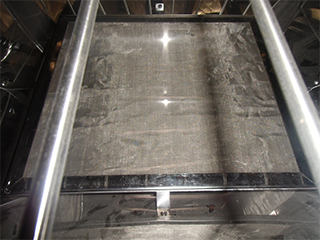

Interior Material | SUS304 stainless steel |

Standard | MIL-STD- 810 |

Product Details

|

|

|

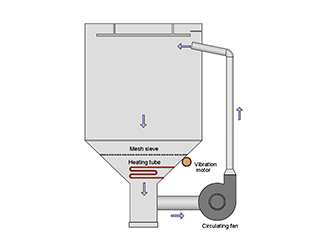

| Dust Circulation System Test chamber with vertical circulating airflow vertical dust circulation system. Airflow can smoothly blow dust into the working room | Electromagnetic Lock Electromagnetic lock to strong lock the door Unlocking is operated on the controller for safety and prevent malfunction。 | Mesh Sieve The mesh sieve is used to filter out clumped or large diameter dust. The diameter of the mesh is 75 um。 |

|

|

Key Features

Mil std 810d Test Chamber simulates real-world sandstorm environments

Customizable test parameters via PLC

Complies with military sand test standards

Standard models according to customers' special requirements

Automatic sand and dust feeding

FAQ

Q: What standards does this Test Chamber meet?

A: It meets MIL-STD-810, IEC 60068-2-68 and other military sand/dust standards.

Q: What sample capacity is available?

A: Chamber volume ranges from 800L to 2000L or custom sizes.

Maintenance and Calibration

Regular maintenance is key to ensuring optimal performance and longevity of the Mil std 810d Test Chamber. Our chambers are designed for easy access to components requiring routine service and calibration. The test space interior, blower assembly, cyclone sand injection system, door seals, controls, and other critical parts can be quickly inspected and maintained without needing major disassembly. We provide detailed preventive maintenance guides so your technicians can keep the chamber in certified working condition. Calibration of temperature, sand velocity sensors, safety systems, and other instrumentation is made simple by user-replaceable parts and calibration procedures.