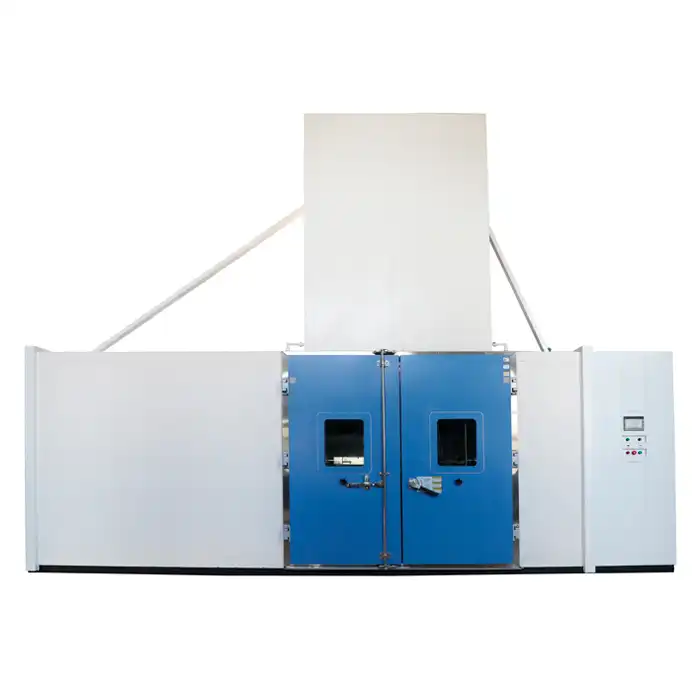

Blowing Rain Test Chamber

Name:blowing rain test chamber

Final rain droplet velocity: 9m/s on test item

Rainfall rate: ≥ 1.7 mm/min

Droplet size: 0.5mm ~ 4.5mm

Test specimen heating range: Water temperature +10°C (max +55°C)

Test time: 0 ~ 999min. adjustable

Nozzle pressure: 276kpa

Rainfall rate: 20.8L/min

Droplet size: 0.5mm ~ 4.5mm

- Product Description

Blowing Rain Test Chamber Manufacturer & Supplier

LIB industry is professional Blowing Rain Test Chamber manufacturers and suppliers in China, to buy or wholesale from our factory. For quotation, contact us now.

The LIB Blowing Rain Test Chamber provides realistic rain simulation testing to evaluate product protection against wind-driven rain. Fully automated operation and data logging ensure efficient testing to industry standards.

LIB MIL-STD 810 rain test chamber is used for evaluating the resistance of a system to water and rain in accordance with MIL-STD-810h.

Technical Parameters

Model | RIM-1000 |

Internal Dimension | 1000*1000*1000 mm D*W*H |

Overall Dimension | 2600*5400*4100 D*W*H |

Interior Volume | 1000L |

The load Turntable | 50kg |

The diameter of Turntable | 800mm |

Rain and Blowing Rain | |

Final rain droplet velocity | 9m/s on test item |

Rainfall rate | ≥ 1.7 mm/min |

Droplet size | 0.5mm ~ 4.5mm |

Test specimen heating range | Water temperature +10°C (max +55°C) |

Test time | 0 ~ 999min. adjustable |

Exaggerated | |

Nozzle pressure | 276kpa |

Rainfall rate | 20.8L/min |

Nozzle amount | One nozzle for each 0.56m2 of surface area and position each about 48cm from in the test surface |

Droplet size | 0.5mm ~ 4.5mm |

Test time | 0 ~ 999min. adjustable |

Drip | |

Drip area dimensions | 1600*1000mm , height can be adjustable |

Drip holes | 20 to 25.4mm |

Distance between hole | 25mm |

Volume of water | ≥280L/m2/h |

Test specimen heating range | Water temperature +10°C (max +55°C) |

Door Lock | Electromagnetic lock |

Exterior Material | A3 Steel Plate with protective coating |

Interior Material | SUS304 stainless steel |

Standard | MIL-STD- 810H |

Product Details

|

|

|

| Workroom The internal material is 304 stainless steel, mirror surface, rust-proof to high and low temperature and moisture corrosion | Build-in lighting The built-in dustproof LED lighting inside the workroom. The light can be turned on and off at the control panel button | Drip Tray The drip tray is made of stainless steel Drip holes are evenly distributed |

|

|

Key Features

●TEMPERATURE

Ambient~80℃

●RAIN AND BLOWING RAIN

1.7 mm/min

●Air velocity 9m/s on test item

●EXAGGERATED

20.8 L/min

●Pressure 276 kpa

●DRIP

280 L/m2/hr

Operating Principle

The blowing rain spray chamber operates on the following principles:

1. The test product is secured in the chamber test space.

2. Test parameters are entered on the HMI, including rainfall rate, wind speed, water temperature, and duration.

3. Upon test initiation, rain simulation, wind generation, and heating activate based on the programmed cycle.

4. Sensors monitor test conditions throughout the duration.

5. At completion, the product is checked for water penetration based on MIL-STD- 810H standards.

6. The control system records data for detailed test reports.

7. The Blowing Rain Test Chamber drains and dries between tests.

FAQ

1. What is the standard chamber size?

The standard chamber provides 1 cubic meter test volume. Larger sizes are available.

2. What wind speeds can be simulated?

Standard horizontal air speeds up to 9m/min. Higher speeds can be accommodated.

3. What after-sales services are offered?

3- years long warranty, and long life service.