Cyclic Corrosion Chamber

Temperature Range:+10 ℃ ~ +90 ℃

Humidity Range:30% ~ 98% RH

Cooling system:Mechanical compression refrigeration system

Air Preheating:Saturated air barrel (31Liter)

Spraying System:Atomizer tower and Spray nozzles

Salt Fog Collected:Fog collector and fog measure cylinder

- Product Description

Cyclic Corrosion Chamber Manufacturer & Supplier

The LIB industry's Cyclic Corrosion Chamber is an advanced, programmable corrosion testing equipment that combines salt spray corrosion with precise control of temperature, humidity, and gaseous corrosives like SO2. It meets international standards such as ASTM G85 for cyclic corrosion testing.

The mechanical refrigeration system with an air-cooled condenser provides precise temperature control from +10°C to +90°C. Saturated air is preheated in a 31-liter barrel before entering the test chamber. The atomizer nozzle tower generates a consistent corrosive salt fog environment throughout the chamber.

Specifications

Model | SC-010 | SC-016 | SC-020 |

Internal dimensions (mm) | 800*1450*680 | 1000*1600*800 | 1000*2000*900 |

Overall dimensions (mm) | 2600×1400×1650 | 2750*1600*1800 | 3150*1600*2100 |

Interior Volume (L) | 780 | 1280 | 1800 |

Temperature Range | +10 ℃ ~ +90 ℃ | ||

Temperature Fluctuation | ± 0.5 ℃ | ||

Temperature Deviation | ± 2.0 ℃ | ||

Humidity Range | 30% ~ 98% RH | ||

Humidity Deviation | + 2%, - 3% | ||

Salt Fog Deposition | 1~2ml / 80cm2 · h | ||

SO2 Gas Control | Control and display volume of SO2 gas | ||

Cooling system | Mechanical compression refrigeration system | ||

Humidifier | External isolation, stainless steel surface evaporation humidifier | ||

Air Preheating | Saturated air barrel | ||

Spraying System | Atomizer tower and Spray nozzles | ||

Salt Fog Collected | Fog collector and fog measure cylinder | ||

Sealing | Pneumatic seal | ||

Controller | Programmable color LCD touch screen controller, Ethernet connection | ||

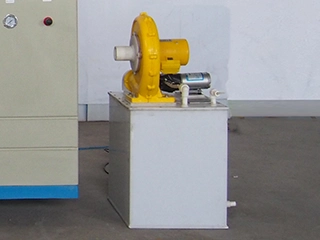

Air Circulation | Centrifugal wind fan | ||

SO2 Exhaust Device | NAOH tank | ||

Safety Device | Humidifier Dry-combustion Protection; Over-temperature Protection; Over-current Protection; Water Shortage Protection; Earth leakage Protection | ||

Material | Glass fiber reinforced plastics | ||

Standard Configuration | 8 round bars and 7 V-shaped grooves | ||

Product Details

|

|

|

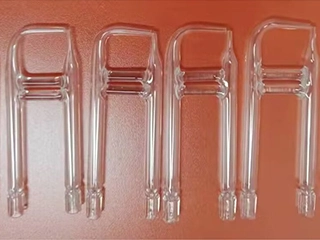

SO2 Exhaust Device After test completed, click “ Exhaust” key to exhaust SO2 from test area to this NAOH tank. This dilutes SO2, to make workplace clean and safe. | Spraing Nozzle Quartz glass Salt spray nozzles are easy to clean and resistant to high temperatures, corrosion, and cloggin | Air Compressor Control The equipment needs a air compressor hole (diameter 13MM), air pressure balance system and water vapor separation system |

|

|

Product Features

Precise temperature and humidity control

Programmable spray cycles with salt fog and SO2 gas

Automated PLC control system

Conforms to ASTM G85 and ISO 9227 standards

Integrated fog collector and measuring cylinder

Key Advantages

Cyclic Corrosion Chamber simulates complex real-world corrosion mechanisms

Allows combined environments (SO2 gas/salt fog/temperature/humidity)

Repeatable and reproducible test results

Complies with major cyclic corrosion standards

Reliable PLC programming and control

Durable construction for long equipment life

FAQ

Q: What standards does this Cyclic Corrosion Chamber comply with?

A: The chamber meets ASTM G85 and ISO 9227 standards for cyclic corrosion testing.

Q: What sample capacity is available?

A: Standard chamber sizes range from 100L to 2500L capacity.

Q: What industries use this type of chamber?

A: Automotive, aerospace, coatings rely on cyclic corrosion testing.