Salt Spray Corrosion Test Chamber

Temperature Range:Ambient: ~ +60 ℃

Humidity Range:95% ~ 98% RH

Salt Fog Deposition:1~2ml / 80cm2 · h

Spray Type: Continuous / Periodic

Materials: Glass fiber reinforced plastics

Standard: ASTMB117, ISO9227

- Product Description

Salt Spray Corrosion Test Chamber Manufacturer & Supplier

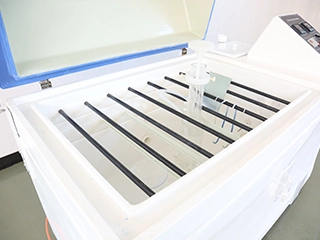

The Salt Spray Corrosion Test Chamber by LIB industry is a meticulously designed and robustly constructed apparatus tailored for assessing the corrosion resistance of materials and coatings under harsh salt fog environmental conditions. It is crafted with materials of glass fiber reinforced plastics to ensure durability and precision in simulating salt spray conditions. With a corrosion-resistant build, this chamber facilitates accurate and reliable testing for a wide array of materials.

Product Parameter:

Model | S-150 | S-250 | S-750 | S-010 | S-016 | S-020 |

Internal dimensions (mm) | 590*470*400 | 1000*640*500 | 1100*750*500 | 1000*1300*600 | 900*1600*720 | 1000*2000*800 |

Overall dimensions (mm) | 1460*760*1140 | 1850*960*1350 | 1950*1030*1350 | 2000×1300×1600 | 2300×1300×1700 | 2700×1300×1900 |

Interior Volume (L) | 110 | 320 | 410 | 780 | 1030 | 1600 |

Temperature Range | Ambient ~ +60 ℃ | |||||

Temperature Fluctuation | ± 0.5 ℃ | |||||

Temperature Deviation | ± 2.0 ℃ | |||||

Humidity Range | 95% ~ 98% RH | |||||

Salt Fog Deposition | 1~2ml / 80cm2 · h | |||||

Spray Type | Continuous / Periodic | |||||

Salt Fog Collected | Fog collector and fog measure cylinder | |||||

Air Preheating | Saturated air barrel | |||||

Spraying System | Atomizer tower and Spray nozzles | |||||

Controller | PID controller | |||||

Safety Device | Humidifier Dry-combustion Protection; Over-temperature Protection; Over-current Protection; Water Shortage Protection; Earth leakage Protection | |||||

Material | Glass fiber reinforced plastics | |||||

Standard Configuration | 6 round bars and 5 V-shaped grooves | |||||

Product Details:

|

|

|

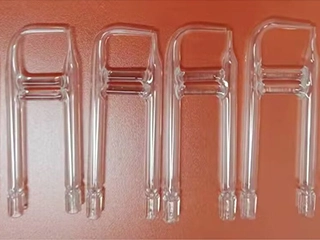

| Controller Network connection computer. Language can be selected, English/French/Spanish/German/Russian | Workroom The material is glass fiber reinforced plastics which has strong corrosion resistance,long service life and high temperature resistance. | Salt Spray Device Nozzle is quartz glass material, wearing parts. Easy to clean and resistant to high temperatures, corrosion, and clogging. |

|

|

Product Features:

Exquisite Craftsmanship: Salt spray corrosion test chamber elegant design with high transparency and a pneumatically operated cover for ease of access.

Durable Materials: Utilizes a PVC plate treated for corrosion resistance, complemented by a plastic steel V-shaped frame and stainless steel angular piping for enhanced durability.

Safety Protections: Equipped with safety features like low water level alerts, over-temperature protection, and overload with short-circuit safeguards.

Water Management System: Features both automatic and manual water replenishment systems to maintain optimal testing conditions.

Customizable Testing: Offers multifunctional settings for test duration with a power outage memory feature to ensure continuity.

Temperature Control: Digital display temperature controller with PID (Proportional-Integral-Derivative) for precise temperature management.

Convenient Design: The water refill bottle is discreetly integrated with a visible water level window, designed for easy maintenance and durability.

How to Test the Corrosion of Paints in a Salt Spray Corrosion Test Chamber?

1. Prepare the test samples: Apply the paint to the metal substrates, ensuring a consistent and uniform coating. Ensure that the samples are clean and free from any contaminants or surface imperfections.

2. Set up the Salt Spray Corrosion Test Chamber: Follow the manufacturer's instructions to set up the test chamber.

3. Place the test samples in the chamber: Arrange the painted samples in the test chamber, ensuring they are adequately spaced to allow proper exposure to the salt spray.

4. Start the corrosion test: Close the chamber and start the test according to the test requirements. The typical duration for a salt spray corrosion test is 24, 48, or 96 hours.

5. Monitor the test samples: Regularly check the samples during the test to assess any visible signs of corrosion, such as blistering, rusting, or peeling of the paint.

6. End the test and evaluate the results: After the desired test duration, stop the salt spray corrosion test and remove the samples from the chamber. Thoroughly inspect each sample for signs of corrosion and compare them to the initial condition. Note any visible corrosion damage and rate the performance of the paint coating.