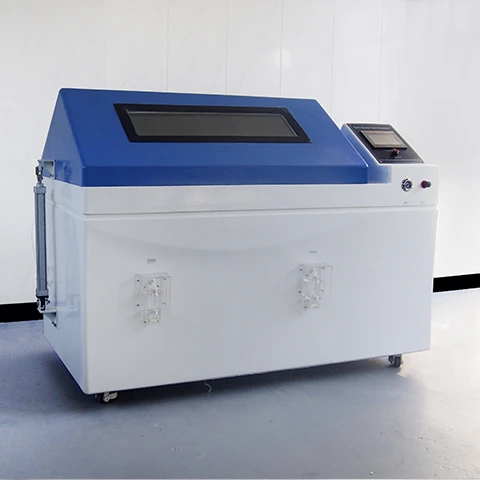

Salt Mist Chamber

Temperature Range:+10 ℃ ~ +90 ℃

Humidity Range:30% ~ 98% RH

Salt Fog Deposition:1~2ml / 80cm2 · h

Cooling system:Mechanical compression refrigeration system

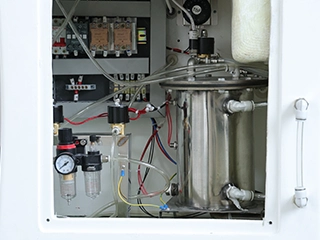

Air Preheating:Saturated air barrel (31Liter)

Spraying System:Atomizer tower and Spray nozzles

- Product Description

Salt Mist Chamber Manufacturer & Supplier

The LIB industry's Salt Mist Chamber is an advanced corrosion test instrument that combines salt mist with precise control of temperature, humidity, and gaseous corrosives like SO2. It conforms to salt spray standards such as ASTM B117 and ISO 9227.

The temperature range is 60°C with an accuracy of ±0.5°C, the humidity range is 98% RH. The atomizer nozzle tower generates a uniform salt fog dispersion at a rate of 1-2 ml/80cm2·h monitored using an integrated fog collector. A programmable PLC allows custom test profile creation. The control system provides real-time monitoring and control.

Specifications

Model | S-150 | S-250 | S-750 | S-010 | S-016 | S-020 |

Internal dimensions (mm) | 590*470*400 | 1000*640*500 | 1100*750*500 | 1000*1300*600 | 900*1600*720 | 1000*2000*800 |

Overall dimensions (mm) | 1460*760*1140 | 1850*960*1350 | 1950*1030*1350 | 2000×1300×1600 | 2300×1300×1700 | 2700×1300×1900 |

Interior Volume (L) | 110 | 320 | 410 | 780 | 1030 | 1600 |

Temperature Range | Ambient ~ +60 ℃ | |||||

Temperature Fluctuation | ± 0.5 ℃ | |||||

Temperature Deviation | ± 2.0 ℃ | |||||

Humidity Range | 95% ~ 98% RH | |||||

Salt Fog Deposition | 1~2ml / 80cm2 · h | |||||

Spray Type | Continuous / Periodic | |||||

Salt Fog Collected | Fog collector and fog measure cylinder | |||||

Air Preheating | Saturated air barrel | |||||

Spraying System | Atomizer tower and Spray nozzles | |||||

Controller | PID controller | |||||

Safety Device | Humidifier Dry-combustion Protection; Over-temperature Protection; Over-current Protection; Water Shortage Protection; Earth leakage Protection | |||||

Material | Glass fiber reinforced plastics | |||||

Standard Configuration | 6 round bars and 5 V-shaped grooves | |||||

Product Details

|

|

|

| Sample shelf Standard sample holder contains 6 round bars and 5 V-shaped grooves for different tests. Special holders can be customized | Saturated Barrel The air is preheated in the saturated barrel. Protection against dry burning. If the water level is low, the spray will stop. | Collecting cup A spray tower comes with a collection cup The two cups collect the salt spray in opposite directions |

|

|

Product Features

●Precise temperature and humidity control

●Adjustable salt fog deposition rate

●Optional SO2 gas injection

●PLC control with touchscreen

●Conforms to salt spray standards

Key Advantages

Salt Mist Chamber Simulates real-world salt atmosphere corrosion

Provides accelerated corrosion testing

Customizable test parameters via PLC

Reliable and repeatable results

Durable body construction

Applications

Salt Mist Chamber has wide applications for testing salt corrosion resistance across multiple industries.

(1)In automotive, it evaluates the corrosion resistance of exterior vehicle panels, wheel alloys, brake components, and chassis parts exposed to road salts.

(2)For aerospace, it tests aluminum, composite surfaces, turbine blades, and landing gear systems used in marine environments.

(3)In defense, it qualifies materials like gun barrels, ammunition, vehicles, ship panels, and aircraft bodies exposed to salt fog, humidity, and coastal conditions.

(4)For oil and gas, it tests offshore platform structural steel, mooring chains, pipelines, valves, and processing equipment meant for marine environments.

(5)In utilities and telecom, it assesses coatings for transmission towers, wind turbines, submarine cables, and antenna finishes against salt atmospheres.

(6)For infrastructure, it tests guard rails, suspension cables, building facades, metal roofing, and construction equipment needing corrosion resistance.

(7)In appliances and electronics, it evaluates exterior component coatings, metal enclosures, and heat exchanger materials requiring protection in coastal areas.