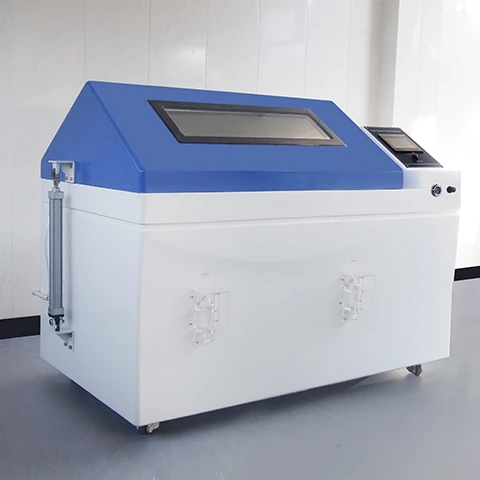

Salt Spray Cabinet

Temperature Range:Ambient: ~ +60 ℃

Humidity Range:95% ~ 98% RH

Spray Type:Continuous / Periodic

Materials: Glass fiber reinforced plastics

Standard:ASTMB117, ISO9227

Volume:110L, 250L, 7500L,1000L, 1500L

- Product Description

Salt Spray Cabinet Manufacturer & Supplier

LIB industry's salt spray cabinet is made of fiberglass, which is solid and durable and can resist corrosion and high temperatures. There are small, medium and large models available, with different sizes and configurations of salt spray chambers available.

Salt spray cabinets are widely used and are very necessary for surface corrosion testing of test samples. Contact us to get detailed data sheet and quotation, we will fast response.

Technical Specifications

Model | S-150 | S-250 | S-750 | S-010 | S-016 | S-020 |

Internal dimensions (mm) | 590*470*400 | 1000*640*500 | 1100*750*500 | 1000*1300*600 | 900*1600*720 | 1000*2000*800 |

Overall dimensions (mm) | 1460*760*1140 | 1850*960*1350 | 1950*1030*1350 | 2000×1300×1600 | 2300×1300×1700 | 2700×1300×1900 |

Interior Volume (L) | 110 | 320 | 410 | 780 | 1030 | 1600 |

Temperature Range | Ambient ~ +60 ℃ | |||||

Temperature Fluctuation | ± 0.5 ℃ | |||||

Temperature Deviation | ± 2.0 ℃ | |||||

Humidity Range | 95% ~ 98% RH | |||||

Salt Fog Deposition | 1~2ml / 80cm2 · h | |||||

Spray Type | Continuous / Periodic | |||||

Salt Fog Collected | Fog collector and fog measure cylinder | |||||

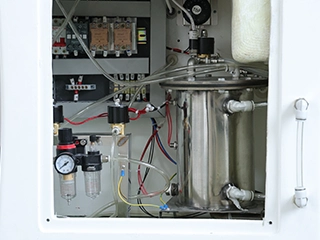

Air Preheating | Saturated air barrel | |||||

Spraying System | Atomizer tower and Spray nozzles | |||||

Controller | PID controller | |||||

Safety Device | Humidifier Dry-combustion Protection; Over-temperature Protection; Over-current Protection; Water Shortage Protection; Earth leakage Protection | |||||

Material | Glass fiber reinforced plastics | |||||

Standard Configuration | 6 round bars and 5 V-shaped grooves | |||||

Product Details

|

|

|

| Saturated Barrel The air is preheated in the saturated barrel. Protection against dry burning. If the water level is low, the spray will stop. | Sample shelf Standard sample holder contains 6 round bars and 5 V-shaped grooves for different tests. Special holders can be customized | Controller PID control system Language can be selected, English/French/Spanish/German/Russian |

|

|

Features

◇Accurate Corrosion Replication: Precisely mimics harsh environments.

◇Consistent Testing Results: Ensures reproducible corrosion test outcomes.

◇Glass fiber reinforced plastics Construction: Resistant to corrosion for prolonged cabinet lifespan.

◇Versatile Sample Capacity: more than 23 differenet models for choose

Application Fields

The Salt Spray Cabinet finds application in automotive, aerospace, coatings, metals, and more. It is instrumental in developing corrosion-resistant materials crucial for product reliability and longevity.

Auto industry

Aerospace

National defense

Navigation

Military products

Metal parts

Telecommunications

Electronic products

Photovoltaic panel

Battery

How Salt Spray Caninet to Test Coatings?

Here are the 8-steps to test Coatings:

1. Preparation: Set up the salt spray chamber according to the manufacturer's instructions. Fill the chamber's reservoir with a salt solution, typically a 5% sodium chloride (NaCl) solution.

2. Sample preparation: Prepare the samples to be tested by applying the coating or protective layer according to the desired specifications. Ensure that the coating is uniformly applied and properly cured or dried.

3. Placement of samples: Place the coated samples inside the salt spray chamber, ensuring that they are adequately spaced apart and not touching each other. Use appropriate holders or racks to suspend the samples to prevent them from coming into contact with the chamber walls or each other.

4. Test parameters: Set the test parameters on the salt spray chamber, including the test duration, temperature, humidity according to test methods.

5. Start the test: Close the chamber and start the salt spray test. The chamber will create a controlled environment with a high concentration of saltwater mist, which will continuously expose the coated samples to the corrosive conditions.

6. Monitoring and evaluation: Regularly monitor the test conditions, including the temperature, humidity, and salt spray concentration inside the chamber, to ensure they remain within the specified ranges. Inspect the samples at regular intervals to evaluate the performance of the coatings and assess any signs of corrosion, such as blistering, rusting, or color changes.

7. Test duration: Keep the samples inside the Salt Spray Cabinet for the specified test duration, which can vary depending on the requirements and standards being followed. Common test durations range from 48 to 1000 hours.

8. Test completion: Once the test duration is completed, remove the samples from the chamber and thoroughly evaluate their performance. Compare the results with the desired performance criteria or standards to determine the effectiveness of the coatings in resisting corrosion.