What is the temperature range of a humidity chamber?

What is the Temperature Range of a Humidity Chamber?

Overall, moisture test cabinets are essential tools for ensuring the dependability and quality of products in a variety of endeavors. By accurately replicating the humidity conditions found in the real world, these chambers enable researchers and manufacturers to proactively identify and address potential issues prior to the release of products. This proactive approach is beneficial to the performance, safety, and durability of the product.

The fundamental function of moisture test cabinets in quality verification is comprehending their functional standards. These chambers precisely regulate the humidity by utilizing cutting-edge systems like humidifiers, dehumidifiers, sensors, and controllers. This ensures consistent and dependable testing conditions for meaningful and reproducible results.

Mugginess test cabinets are used by industries like aviation, medicine, the automobile, and hardware to see how well products and materials stand up to moisture. By evaluating the long-term reliability of electronic components and circuit boards in humid conditions, these chambers, for instance, aid in the prevention of failures caused by corrosion or electrical malfunctions in the field of electronics. Stickiness testing ensures the stability and viability of medications in damp environments, safeguarding patient health.

Making a strategic investment in high-quality humidity test cabinets is an option for businesses that are serious about enhancing product development procedures and adhering to stringent quality control standards. These chambers can be utilized by businesses to enhance product designs, acquire useful data on product performance, and ultimately introduce safer and more dependable products to the market.

If it's not too much trouble, go ahead and reach us at info@libtestchamber.com for extra data with respect to mugginess test cupboards and the applications they have that are custom fitted to the prerequisites of your industry. With our knowledge and solutions, we are here to assist you in achieving your quality assurance goals.

Understanding Environmental Chambers

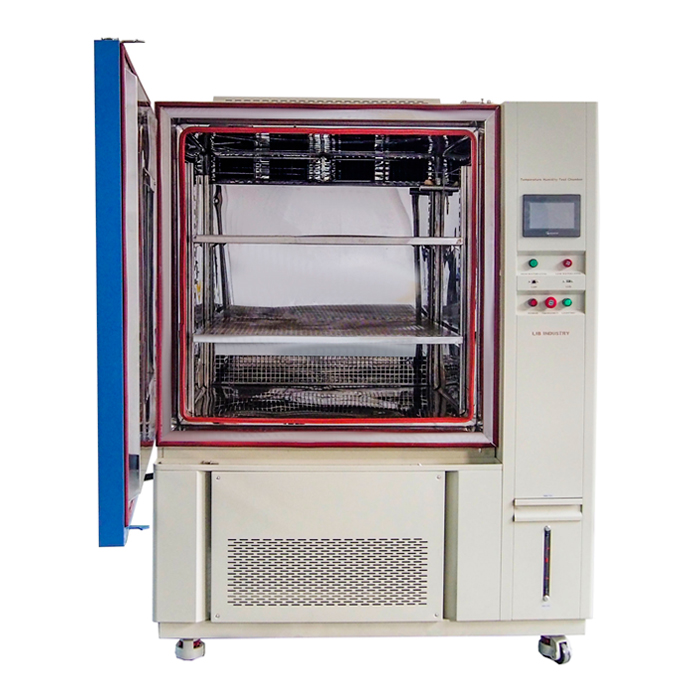

Controlled environments that simulate real-world scenarios or extremes encountered during a product's lifecycle are provided by environmental chamber humidity, which are meticulously designed to replicate precise temperature and humidity conditions. These chambers are essential in a variety of industries, including pharmaceuticals, electronics, automotive, and others, where product performance and dependability are of the utmost importance.

Biological chambers expect a basic part in drug applications while testing the security and uprightness of prescriptions and vaccinations under various normal conditions. By exposing drug products to controlled temperature and mugginess conditions, producers can evaluate their performance during capacity and transportation, ensuring strength and user safety.

Environmental chamber humidity are required in the electronics industry for assessing devices' and components' resistance to temperature and humidity. Testing under these controlled circumstances recognizes potential defects that could appear in different conditions or useful circumstances, for example, electrical or utilization issues.

The solidity and performance of vehicle components and materials in extreme weather conditions are supported by normal chambers used by automobile manufacturers. Planners can evaluate car parts' protection from wear, rot, and essential decency over the long haul by exposing them to reenacted heat, cold, tenacity, and salt splash.

The aerospace industry tests the dependability of aircraft components and materials in extreme temperatures and at high altitudes using environmental chamber humidity' adaptability. Before they can be used, aerospace technologies must meet strict operational and safety standards.

In general, environmental chambers are useful tools in a wide range of industries for quality control and R&D. These chambers enable manufacturers to innovate with confidence, reduce risks, and deliver products that meet the highest performance, durability, and safety standards by creating controlled environments that mimic real-world conditions.

Exploring Temperature Control in Humidity Chambers

Temperature control within a humidity chamber is critical because it directly affects how other parameters, especially humidity, behave within the chamber. Most modern chambers offer a broad temperature range to accommodate various testing needs. Typically, these chambers can maintain temperatures ranging from as low as -70°C to as high as 180°C, covering a wide spectrum of environmental conditions.

The ability to control temperature with such precision allows researchers and engineers to simulate everything from Arctic conditions to scorching desert heat, depending on the testing requirements of the product being evaluated. This versatility ensures that products are tested comprehensively against temperature extremes they might face during storage, transport, or use.

Importance of Humidity Control

While temperature range is a significant aspect, humidity control is equally crucial in environmental chamber humidity. Humidity levels can drastically impact how materials and products behave under test conditions. Chambers are equipped to control humidity levels from 10% RH to 98% RH, creating environments that can be bone-dry or extremely humid, depending on the testing protocols.

The ability to adjust humidity alongside temperature provides a holistic testing environment, ensuring that products can withstand not only temperature extremes but also varying levels of moisture in the air. This capability is particularly valuable for industries where environmental conditions play a critical role in product performance and reliability.

Applications Across Industries

The versatility of humidity chambers makes them indispensable in various industries:

- Electronics: Testing electronic components under extreme temperatures and humidity levels ensures their reliability in diverse climates.

- Pharmaceuticals: Stability testing of drugs requires precise control over temperature and humidity to maintain efficacy.

- Automotive: Testing components ensures they can withstand temperature fluctuations and humidity, crucial for vehicle performance.

- Aerospace: Simulating space conditions to test equipment durability under extreme temperature and humidity variations.

Conclusion

In conclusion, the temperature range of a humidity chamber is pivotal in creating controlled environments for testing products across industries. By offering precise control over temperature and humidity, these chambers enable researchers and manufacturers to validate the reliability and durability of their products under various environmental conditions. Whether testing the resilience of electronic components or the stability of pharmaceuticals, humidity chambers play a crucial role in ensuring product quality and performance.

For businesses looking to enhance their testing capabilities or learn more about environmental chambers and humidity control, exploring comprehensive solutions from experts like LIB can provide valuable insights and tailored equipment options. Understanding these chambers' capabilities empowers industries to innovate confidently, knowing their products are rigorously tested for real-world conditions.

Remember, for more information on environmental chamber humidity and comprehensive testing solutions, feel free to reach out to LIB. Our experts are ready to assist you in finding the right environmental testing solution for your specific needs.