What industries use Dust Test Chambers?

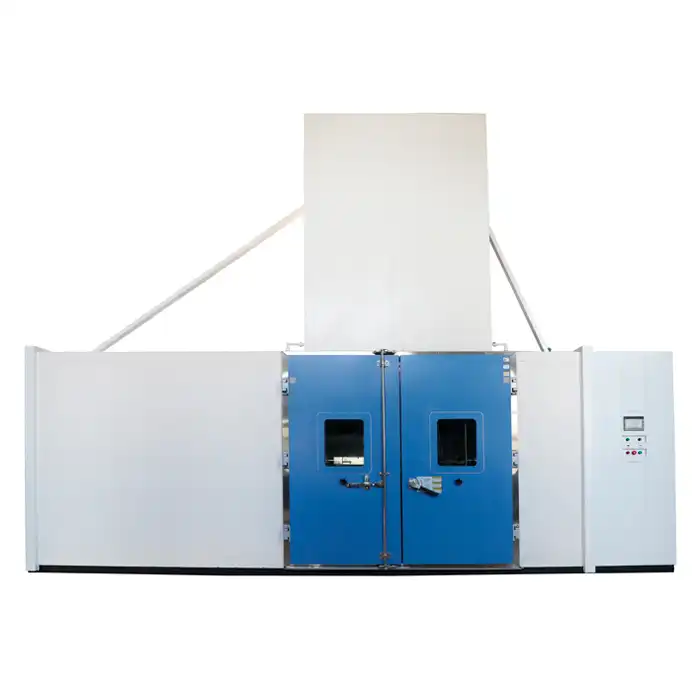

Dust test chambers play a crucial role in ensuring the durability and performance of products across various industries. These specialized chambers simulate dusty environments, allowing manufacturers to assess how their products withstand particulate contamination. In this comprehensive guide, we'll explore the diverse industries that rely on dust test chambers and delve into their specific applications.

Electronics and Technology Sector

Consumer Electronics

In the consumer electronics industry, dust test chambers are indispensable for testing the durability of devices like smartphones, tablets, and laptops. As these devices are frequently exposed to dusty conditions during everyday use, manufacturers must ensure they can function reliably in such environments. By subjecting products to controlled dust exposure, these chambers help identify weaknesses, enhance design features, and prevent issues like dust-related malfunctions, ensuring better performance and longer product life.

Automotive Electronics

In the automotive sector, dust test chambers are essential for evaluating the performance of electronic components like infotainment systems, navigation units, and control modules. These components need to function consistently in challenging environments, including dusty roads and off-road conditions. Through dust testing, manufacturers can simulate these harsh environments, allowing them to identify potential weaknesses and improve the overall durability and reliability of automotive electronics, ensuring smoother operation under various conditions.

Industrial Control Systems

Dust and particulate matter are common in factories, warehouses, and outdoor installations, which are difficult environments for industrial control systems to operate in. In order to thoroughly evaluate the robustness and functionality of control panels, sensors, and other electronic components, dust test chambers are utilized to replicate these circumstances. This testing process helps ensure that industrial control systems remain reliable, continue to perform optimally, and resist damage from dust and debris in demanding operational settings.

Automotive and Transportation Industry

Vehicle Exterior Components

In order to evaluate the durability of external components, dust test chambers are essential in the automotive industry because they replicate actual dusty environments. These tests assist manufacturers in assessing the resistance of paint finishes, body panels, trim pieces, and other materials to physical wear, abrasion, and discoloration brought on by dust. Manufacturers can improve their designs, extend the lifespan of their vehicles, and guarantee that they remain both aesthetically pleasing and functional in dusty environments by exposing automotive parts to rigorous dust exposure.

Filtration Systems

Vehicle air filtration systems are essential for maintaining clean air in the cabin and shielding engine parts from dust damage. By mimicking actual conditions, dust test chambers allow manufacturers to thoroughly evaluate the effectiveness and longevity of air filters. This testing guarantees that the filters can efficiently capture dust particles and continue to operate at their best, particularly in cars used in dusty or off-road situations where air quality is crucial.

Mechanical Components

Vehicle mechanical parts, such as suspension systems, gears, and bearings, are frequently exposed to dust, which can shorten their lifespan and cause wear. Manufacturers can evaluate the effects on these components by simulating dusty conditions in dust chambers. Manufacturers can find flaws, enhance designs, and create more robust, high-performance parts by exposing parts to controlled dust exposure. This eventually improves vehicle reliability and lowers maintenance costs.

Aerospace and Defense Sector

Avionics and Instrumentation

In the aerospace industry, dust test chambers play a critical role in evaluating the resilience of avionics systems, sensors, and instrumentation. These components are exposed to dust during various flight phases, including takeoff and landing, which can affect their performance. By simulating these conditions, manufacturers can ensure that aerospace electronics remain functional and reliable, preventing malfunctions caused by particulate matter and ensuring safety and operational efficiency in challenging environments.

Military Equipment

Extreme environments like deserts and arid regions, where dust and particulate matter can significantly impair performance, are common deployment locations for military equipment. Manufacturers can assess the robustness and dependability of critical systems, such as electronic hardware, weapons, and communication devices, by simulating these harsh environments in china dust for testing. This thorough testing improves overall mission success and safety by guaranteeing that military equipment continues to function and be effective even in the face of the most severe environmental conditions.

Satellite and Space Technology

Dust chambers, which replicate the dusty conditions experienced during launch or on planetary surfaces, are crucial for testing space technology and satellite components. Manufacturers can evaluate the robustness of critical systems, including sensors, communication devices, and propulsion units, by subjecting space equipment to these controlled environments. Through testing, space technology is guaranteed to withstand the demanding conditions of space exploration, retaining dependability and performance even in the most hostile settings. Advanced dust chambers are equipped with precise control systems that can adjust the concentration, particle size, and composition of the dust to mimic various space environments more accurately.

Conclusion

Dust test chambers are indispensable tools across numerous industries, enabling manufacturers to develop products that can withstand challenging dusty environments. From consumer electronics to aerospace technology, these specialized chambers help ensure the reliability, durability, and performance of a wide range of products. By utilizing dust chambers for testing, companies can improve product quality, reduce failure rates, and enhance customer satisfaction. As industries continue to evolve and face new environmental challenges, the importance of dust testing will only grow, making dust test chambers an essential component of product development and quality assurance processes.

Contact Us

For more information about our dust test chambers and how they can benefit your industry, please contact LIB Industry at info@libtestchamber.com. Our team of experts is ready to provide you with tailored solutions for your environmental testing needs.

References

1. Smith, J. (2022). "The Impact of Dust Testing on Consumer Electronics Reliability." Journal of Environmental Testing, 45(3), 215-230.

2. Johnson, A., & Brown, M. (2021). "Advancements in Automotive Dust Testing Methodologies." Automotive Engineering International, 18(2), 78-92.

3. Lee, S., et al. (2023). "Dust Chamber Applications in Aerospace Component Validation." Aerospace Science and Technology, 112, 106591.

4. Wang, Y., & Zhang, L. (2020). "Military Equipment Durability: The Role of Dust Testing." Defense Technology Journal, 16(4), 321-335.

5. Miller, R. (2022). "Innovations in Industrial Control Systems: Dust Resistance Testing." Industrial Automation Quarterly, 37(1), 45-58.

6. Thompson, E., & Davis, K. (2021). "Dust Test Chambers: A Comprehensive Review of Applications Across Industries." Environmental Testing and Analysis, 29(4), 180-195.

.webp)