UVA vs. UVB: Understanding the Application and Differences of UV Light Sources in Accelerated Weathering Testing

Choosing the right UV light source for accelerated weathering is essential, as different materials react to UVA and UVB exposure in unique ways. In this blog, we'll explore the differences between UVA and UVB radiation and how they are applied in UV accelerated machines for effective weathering tests.

UVA Radiation: Wavelength, Penetration, and its Role in Material Degradation

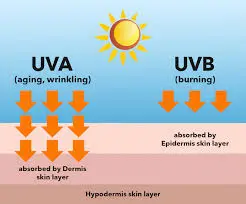

UVA radiation has longer wavelengths, typically ranging from 315 to 400 nanometers (nm). Due to its lower energy compared to UVB, it penetrates deeper into materials without causing immediate surface damage. However, prolonged exposure can lead to material degradation, including fading, discoloration, and loss of tensile strength. UVA is often used in accelerated weathering tests to simulate long-term exposure to sunlight, especially when a product is expected to endure gradual wear over time.

In industries such as automotive coatings and outdoor furniture manufacturing, UVA testing is crucial to ensure that materials can resist prolonged exposure without losing their appearance or structural integrity.

UVB Radiation: Higher Energy, Accelerated Damage, and Specific Material Interactions

UVB radiation, with wavelengths between 280 and 315 nm, carries significantly more energy than UVA. This higher energy results in faster surface degradation, making UVB ideal for simulating harsher, short-term exposure to sunlight. Materials exposed to UVB radiation can experience rapid cracking, fading, or embrittlement, especially in plastics, coatings, and polymers.

UVB is regularly used in a UV accelerated machine when manufacturers need to simulate extreme environmental conditions in a shorter period of time. For example, packaging materials or outdoor signs may need UVB testing to ensure they can withstand the intense sunlight in certain climates.

Key Spectral Differences: the Wavelength and Penetration power

One of the most significant differences between UVA and UVB radiation is their respective wavelengths, which influence how they interact with different materials. UVA lamps, emitting longer wavelengths (315-400 nm), are generally used for testing materials that require long-term durability against sunlight. These materials, such as automotive paints and textiles, may degrade slowly over time, with gradual color fading or weakening.

On the other hand, UVB lamps produce shorter wavelengths (280-315 nm) that deliver higher energy. This energy is absorbed more intensely by the surface of materials, leading to quicker degradation. UVB lamps are often used in accelerated weathering tests to mimic the kind of damage caused by intense, direct sunlight in tropical or high-altitude environments.

Another significant difference is penetration. UVA has stronger penetration (more than 90% of ultraviolet light is UVA). It can penetrate glass, even nine feet of water; however, the shorter wavelength of UVB is absorbed by the clear glass.

Matching the Light Source to the Material: Applications of UVA and UVB in Diverse Industries

Accelerated weathering testing using a UV accelerated machine is an essential step in product development for a wide range of industries including automotive, aerospace and consumer products. The choice between UVA and UVB radiation depends on the specific material being tested and the environmental conditions it will face.

For instance, in the automotive industry, both UVA and UVB testing are used to assess the durability of exterior paints and coatings. UVA tests simulate the long-term effects of everyday sun exposure, while UVB tests accelerate the damage caused by extreme sunlight conditions. In contrast, industries like plastics manufacturing typically use UVB testing to evaluate the impact of ultraviolet radiation on the structural integrity of materials, ensuring products like outdoor furniture and packaging materials can withstand direct sunlight without deteriorating quickly.

Data from previous studies show that materials exposed to UVB radiation degrade up to five times faster than those exposed to UVA. This makes UVB the preferred choice for testing materials that will face intense, short-duration sunlight, while UVA is ideal for products designed to endure long-term exposure.

LIB UV Accelerated Machine

LIB Industry offers cutting-edge UV accelerated machines designed to meet the diverse needs of manufacturers conducting weathering tests. These machines simulate both UVA and UVB radiation, allowing for comprehensive material testing. By offering precise control over wavelength exposure, LIB's UV accelerated machines provide manufacturers with the ability to simulate real-world environmental conditions in a controlled lab setting. Some of the key advantages of LIB's UV accelerated testing machines include:

- Versatility: Capable of simulating both UVA and UVB light sources, allowing for a wide range of material tests.

- Precision: Advanced controls offer accurate regulation of irradiation and temperature, ensuring reliable test results.

- Durability: Built with high-quality materials to ensure long-lasting performance, even under continuous use.

- User-friendly: Intuitive interfaces make it easy to operate and customize testing parameters.

| Irradiation Source: Fluorescent UV lamps (8) - 40 W Temperature Range: Ambient ~ 90 ℃ ±2℃ Black Panel Temperature (BPT): 35 ~ 80 ℃ Humidity Range: ≥95% RH Bandwidth: 290 ~ 400 nm Irradiance Control: 0.3~20 W/㎡ Water Spray Cycle: 1~9999H59M (Adjustable) Distance of Specimen and lamp: 50 mm |

These machines are ideal for industries such as automotive, aerospace, packaging, and construction, providing essential data about how materials will perform under long-term UV exposure. To learn more about LIB's UV accelerated machines, or to request a quote, contact us at ellen@lib-industry.com.

References

1. "Ultraviolet Radiation and Its Effects on Materials," Journal of Materials Science, 2021.

2. "Accelerated Weathering Testing: UVA vs. UVB," International Journal of Polymer Science, 2020.

3. "Photodegradation of Polymers: UVA and UVB Testing Insights," Polymer Degradation and Stability, 2019.

4. "Comparing UVA and UVB Lamps in Accelerated Weathering Tests," Surface Coatings Technology Review, 2022.

5. "UV Radiation Effects on Automotive Coatings," Journal of Coatings Technology and Research, 2021.