Xenon Test Chamber

Irradiance Range:35~150 W/㎡

Bandwidth Measurement:300nm~400nm (340nm or 420nm)

Cooling System: Mechanical compression refrigeration system

Exterior Material: Steel plate with protective coating

Interior Material:SUS304 stainless steel

Thermal Insulation: Polyurethane foam and insulation cotton

- Product Description

Xenon Test Chamber Manufacturer & Supplier

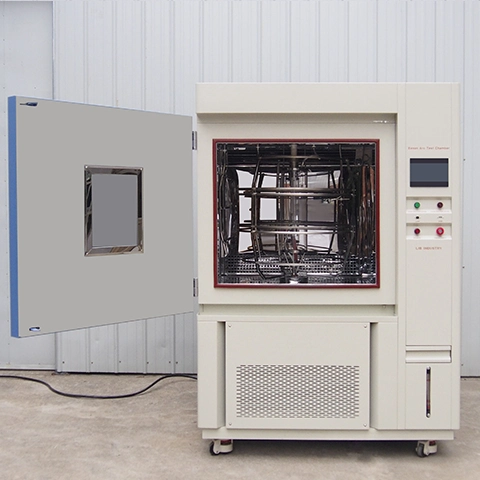

LIB industry's xenon test chamber is a a reliable accelerated aging equipment designed to replicate sunlight through a xenon arc lamp. It assesses material durability and resistance to weathering factors such as sunlight exposure, temperature variations, and moisture.

Our xenon chamber adheres to international standards like ASTM G155 and ISO 4892, ensuring precise simulation of sunlight for testing material aging and durability.

Technical Specifications

Model | XL-S-750 |

Internal Dimension (mm) | 950*950*850 mm |

Overall Dimension (mm) | 1400*1400*1950 mm |

Specimen Holder Size(mm) | 95*200 |

Specimen Capacity | 42pcs |

Chamber Type | Rotating Holder |

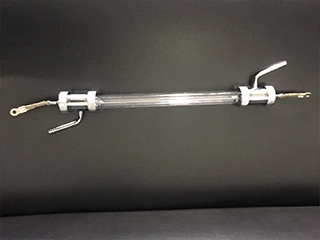

Irradiation Source | 1 piece of 4500w water-cooled xenon arc lamp |

Irradiance Range | 35~150 W/㎡ |

Bandwidth Measurement | 300nm~400nm (340nm or 420nm) |

Chamber Temperature Range | Ambient ~ 100 ℃ ±2℃ |

Black Panel Temperature | BPT 35 ~ 85 ℃ ±2℃ |

Humidity Range | 50% ~ 98% RH |

Humidity Deviation | ± 5% RH |

Water Spray Cycle | 1~9999H59M (Adjustable) |

Controller | Programmable color LCD touch screen controller |

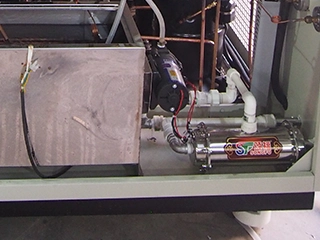

Water supply system | Automatic water supply, Water purification system |

Radiometer | UV Radiometer, Tolerance: ±5% |

Cooling System | Mechanical compression refrigeration system |

Humidification System | External isolation, stainless steel surface evaporation humidifier |

Safety Device | Over-temperature Protection; Over-current Protection; Water Shortage Protection; Earth leakage Protection; Phase Sequence Protection |

Exterior Material | Steel plate with protective coating |

Interior Material | SUS304 stainless steel |

Thermal Insulation | Polyurethane foam and insulation cotton |

Observation Window | Interior lighting, double-layer thermo stability silicone rubber sealing |

Product Details

|

|

|

| Irradiation Source Irradiation Source with 1 piece of 4500 W water-cooled xenon lamp Various filters available for choose | Water Re-circulation Water purifier: mainly purification from water source to water tank. Automatic water supply | Water Spray Water spray pipe is equipped with nozzles Simulates the outdoor moisture to the material |

|

|

Xenon Test Chamber Functions

1. Sunlight Simulation:

The primary function of the Chamber is to replicate sunlight using a xenon arc lamp. This lamp produces a spectrum of light that natural sunlight, including ultraviolet (UV) radiation.

2. UV Exposure Testing:

The xenon test chamber is designed to subject materials to controlled UV exposure, allowing for the assessment of how materials react to prolonged exposure to UV radiation. This is crucial for understanding the impact of sunlight on material durability.

3. Temperature Variation Simulation:

The chamber can replicate temperature variations to simulate the conditions materials may experience in real-world environments. This is important for assessing how temperature changes affect material properties over time.

Xenon Test Chamber Application Fields

1. Automotive industry: Xenon Test Chamber is used to test the durability and colorfastness of automotive paints, interior materials, and exterior components.

2. Aerospace industry: In the aerospace industry, xenon weathering chambers are used to simulate the harsh conditions that aircraft components may encounter during their operational lifespan.

3. Building materials: Xenon weathering chambers are used to test the durability and color stability of various building materials, such as roofing materials, exterior cladding, and window frames.

4. Textile industry: Test the colorfastness and durability of textiles, such as clothing, upholstery, and outdoor fabrics.

4. Paint and coatings industry: Xenon weathering chambers are widely used in the paint and coatings industry to evaluate the long-term performance and color stability of various coatings, including architectural paints, industrial coatings, and automotive finishes.

FAQ

Q: What standards does the test chamber comply with?

A: The chamber adheres to international standards such as ASTM G155 and ISO 4892 for accurate sunlight simulation.

Q: Can this chamber accommodate various sample sizes?

A: Yes, It can be configured to accommodate different sample sizes for comprehensive testing.