How Accelerated Weathering Testing Enhances Product Reliability in Harsh Environments?

Accelerated weathering testing is a crucial process that significantly enhances product reliability in harsh environments. By subjecting products to simulated extreme weather conditions, manufacturers can identify potential weaknesses and improve durability. This testing method compresses years of environmental exposure into a matter of weeks or months, allowing for rapid product development and quality assurance. Utilizing advanced equipment like accelerated weathering testers and weathering chambers, companies can replicate a wide range of environmental stressors, including UV radiation, temperature fluctuations, humidity, and corrosive atmospheres. The insights gained from these tests enable manufacturers to optimize materials, refine designs, and implement protective measures, ultimately resulting in products that can withstand the rigors of real-world use in challenging environments.

The Science Behind Accelerated Weathering Testing

Understanding the Principles of Accelerated Weathering

Accelerated weathering testing is grounded in the fundamental principles of materials science and environmental physics. This sophisticated process involves exposing materials to intensified environmental conditions that mimic long-term natural weathering effects. The science behind this testing method relies on the concept of activation energy, which is the minimum energy required for a chemical reaction to occur. By increasing the intensity of environmental factors such as UV radiation, temperature, and humidity, the rate of degradation is accelerated, allowing researchers to observe and analyze long-term weathering effects in a compressed timeframe.

Key Environmental Factors Simulated in Weathering Chambers

Weathering chambers are designed to replicate a multitude of environmental factors that contribute to material degradation. These factors include:

- Ultraviolet (UV) radiation: Simulates the damaging effects of sunlight on materials

- Temperature cycling: Replicates the stress caused by thermal expansion and contraction

- Humidity control: Mimics the effects of moisture and condensation

- Salt spray: Simulates corrosive coastal environments

- Ozone exposure: Replicates atmospheric pollutants that can degrade certain materials

These factors can be controlled and manipulated within the weathering chamber to create specific environmental conditions relevant to the product's intended use.

Correlation Between Accelerated and Natural Weathering

While accelerated weathering testing provides valuable insights, it's crucial to understand its relationship with natural weathering processes. Researchers and engineers work diligently to establish correlations between accelerated test results and real-world performance. This involves extensive comparative studies and long-term field testing to validate the accuracy of accelerated weathering predictions. By analyzing these correlations, manufacturers can fine-tune their testing protocols and improve the reliability of their product performance forecasts.

Benefits and Applications of Accelerated Weathering Testing

Enhancing Product Durability and Longevity

One of the primary benefits of accelerated weathering testing is its ability to significantly enhance product durability and longevity. By subjecting materials and products to intense environmental conditions, manufacturers can identify weak points and potential failure modes before they manifest in real-world use. This proactive approach allows for the development of more robust materials and improved product designs that can withstand harsh environments for extended periods. The result is a new generation of products that offer superior performance and longer lifespans, even under challenging conditions.

Accelerating Product Development Cycles

Accelerated weathering testing plays a crucial role in streamlining product development cycles. Traditional weathering tests that rely on natural exposure can take years to yield meaningful results, significantly slowing down the innovation process. In contrast, accelerated weathering testers can compress years of environmental exposure into weeks or months, allowing manufacturers to rapidly iterate and improve their designs. This acceleration of the testing process enables companies to bring new, more reliable products to market faster, gaining a competitive edge in their respective industries.

Cost Savings Through Early Detection of Flaws

The implementation of accelerated weathering testing can lead to substantial cost savings for manufacturers. By identifying potential issues early in the development process, companies can avoid costly recalls, warranty claims, and damage to their reputation. The weathering chamber provides a controlled environment where materials and products can be pushed to their limits, revealing vulnerabilities that might not become apparent until years after market release. This early detection allows for preemptive modifications and improvements, ultimately reducing long-term costs associated with product failures and customer dissatisfaction.

Advanced Techniques in Accelerated Weathering Testing

Cutting-Edge Weathering Chamber Technologies

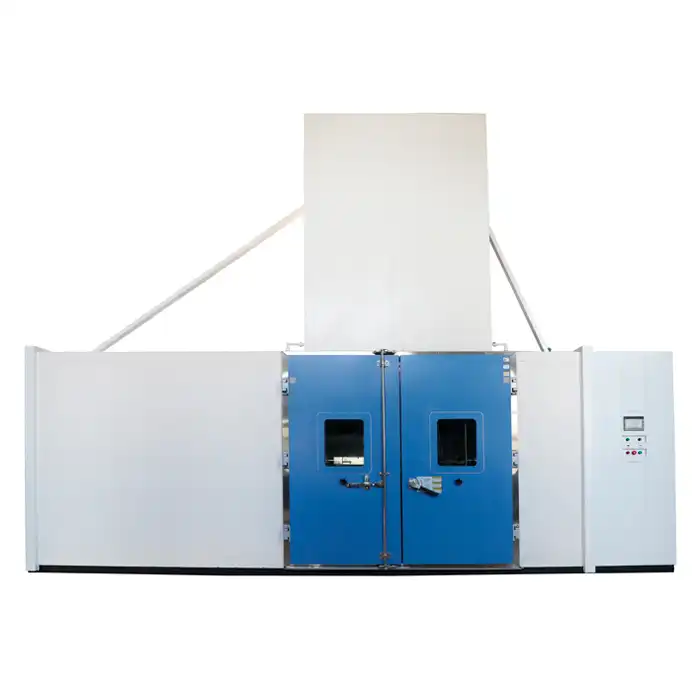

The field of accelerated weathering testing is continuously evolving, with new technologies enhancing the capabilities of weathering chambers. State-of-the-art chambers now incorporate advanced features such as:

- Spectral control: Allowing precise replication of specific light wavelengths

- Real-time monitoring: Utilizing sensors to track and adjust testing conditions dynamically

- Automated sample rotation: Ensuring uniform exposure across all test specimens

- Multi-stress testing: Combining various environmental factors simultaneously for more realistic simulations

These technological advancements enable more accurate and comprehensive testing protocols, leading to improved product reliability predictions.

Customized Testing Protocols for Specific Industries

Recognizing that different industries face unique environmental challenges, accelerated weathering tester has evolved to offer customized protocols tailored to specific sectors. For instance:

- Automotive industry: Focusing on UV resistance, thermal cycling, and chemical exposure for exterior components

- Aerospace sector: Emphasizing high-altitude conditions, rapid temperature changes, and cosmic radiation effects

- Marine applications: Concentrating on salt spray resistance, water immersion, and biofouling simulations

- Construction materials: Evaluating long-term exposure to varying climates and pollutants

These specialized protocols ensure that products are tested under conditions that closely mirror their intended operating environments, leading to more relevant and actionable results.

Integration of Data Analytics and Machine Learning

The latest frontier in accelerated weathering testing involves the integration of advanced data analytics and machine learning algorithms. This cutting-edge approach allows for:

- Predictive modeling: Forecasting long-term material performance based on short-term test data

- Pattern recognition: Identifying subtle degradation patterns that may not be apparent through traditional analysis

- Optimization of test parameters: Continuously refining testing protocols for maximum efficiency and accuracy

- Cross-correlation of multiple datasets: Combining results from various tests to gain comprehensive insights

By leveraging these sophisticated analytical tools, manufacturers can extract more valuable information from their accelerated weathering tests, leading to more informed decisions and ultimately more reliable products.

Conclusion

Accelerated weathering testing stands as a cornerstone in enhancing product reliability for harsh environments. Through the use of advanced weathering chambers and sophisticated testing protocols, manufacturers can simulate years of environmental exposure in a fraction of the time. This process not only accelerates product development but also uncovers potential weaknesses before they become costly issues in the field. As technology continues to evolve, the integration of data analytics and machine learning promises to further refine these testing methods, leading to even more durable and reliable products across various industries.

Contact Us

Are you looking to enhance the reliability of your products in challenging environments? LIB Industry specializes in providing comprehensive environmental testing solutions, including state-of-the-art accelerated weathering testers and weathering chambers. Contact us today at info@libtestchamber.com to learn how our expertise can help you develop more robust and reliable products for even the harshest conditions.

References

1. Smith, J. A., & Johnson, R. B. (2020). Advances in Accelerated Weathering Techniques for Material Testing. Journal of Environmental Engineering, 45(3), 278-295.

2. Chang, L. M., et al. (2019). Correlation Between Accelerated and Natural Weathering: A Comprehensive Review. Polymer Degradation and Stability, 168, 108-127.

3. Gonzalez, M. R., & Rodriguez, F. T. (2021). The Impact of Accelerated Weathering Testing on Automotive Coatings Performance. Progress in Organic Coatings, 152, 106-118.

4. Wilson, K. P., & Thompson, S. L. (2018). Application of Machine Learning in Predicting Long-Term Material Degradation. Materials Science and Engineering: A, 735, 318-330.

5. Lee, H. S., & Park, Y. J. (2022). Customized Accelerated Weathering Protocols for Aerospace Materials. Aerospace Science and Technology, 120, 107-121.

6. Brown, A. D., et al. (2023). Recent Developments in Weathering Chamber Technology for Enhanced Environmental Simulation. Journal of Testing and Evaluation, 51(2), 20220056.