Best Practices for Assembling Salt Fog Test Equipment Safely

Salt fog test equipment plays a critical role in assessing the durability and corrosion resistance of materials and coatings under harsh environmental conditions. Assembling this equipment safely and effectively is essential to ensure accurate results and avoid unnecessary risks. Below, we explore the best practices to follow when assembling your salt fog test equipment.

Using Personal Protective Equipment (PPE) During Assembly

Personal protective equipment (PPE) is essential for ensuring safety during the assembly process. Wear gloves to protect your hands from sharp edges or corrosive materials, and goggles to shield your eyes from accidental splashes of saline solution.

If your workspace lacks proper ventilation, consider wearing a respirator mask to minimize exposure to airborne particles. Long-sleeved clothing and anti-slip footwear are also recommended to prevent injuries. Proper PPE reduces the risk of accidents, allowing you to work confidently and safely.

Preparing Your Workspace: Essential Safety Measures

A well-organized and safe workspace is the foundation of any successful assembly process. Begin by selecting a clean, dry, and well-lit environment to reduce the likelihood of accidents or contamination. Ensure that your workspace is free of unnecessary clutter, as stray tools or debris can interfere with the assembly process.

Verify that your workbench or assembly area is stable and large enough to support the salt fog test equipment. Maintain proper ventilation to avoid exposure to test solutions, which can sometimes include corrosive substances. Additionally, keep a fire extinguisher, first aid kit, and emergency contact numbers readily accessible. These precautions will minimize risks and help you complete the assembly process without complications.

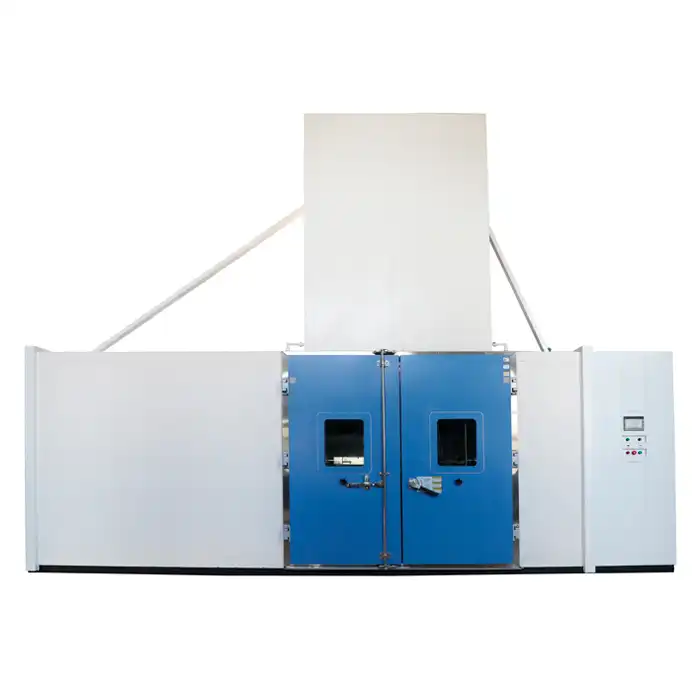

Understanding Equipment Components and Their Functions

Before diving into the assembly process, familiarize yourself with the key components of your salt fog test equipment. Understanding the purpose and function of each part will not only help with proper installation but also prevent damage during assembly.

For example, most salt fog test chambers include components such as:

- Atomizing nozzles: These create the fine mist required for consistent testing conditions.

- Salt solution reservoir: This holds the saline solution used during testing.

- Control panels: These allow users to set and monitor test parameters like temperature, humidity, and spray duration.

- Sealing gaskets: These ensure that the chamber remains airtight during tests.

Take the time to review the salt fog test equipment manufacturer's assembly manual, paying close attention to any warnings or specific instructions provided. This initial preparation will ensure that each part functions as intended after assembly.

Step-by-Step Assembly Guide: Ensuring Proper Installation

Proper assembly is vital to the performance and longevity of your salt fog test equipment. Follow these steps to ensure safe and effective installation:

Inspect All Components

Before beginning, inspect all parts for damage or defects. Look for cracks, dents, or missing pieces that could hinder performance. If you detect any issues, contact your salt fog test equipment manufacturer for replacement parts.

Secure the Base and Framework

Start by setting up the base and framework of the chamber, ensuring everything is level and stable. Use a spirit level to check the alignment, as uneven surfaces can affect test accuracy. Tighten bolts and screws securely, but avoid overtightening, which could damage components.

Install the Atomizing Nozzle System

Attach the atomizing nozzles according to the manufacturer's guidelines. Ensure that the nozzles are positioned correctly to distribute mist evenly throughout the salt fog test equipment. Improper placement can lead to inconsistent test results.

Connect Electrical and Control Components

Carefully connect the control panel to the power source and testing equipment. Double-check wiring for accuracy and ensure connections are secure. Avoid leaving wires exposed, as this poses a safety hazard.

Seal the Chamber Properly

Install sealing gaskets around the chamber doors to create an airtight environment. A proper seal prevents the escape of salt mist, protecting both the workspace and the integrity of your tests.

Test for Functionality

Once assembled, perform a dry run to verify that all components are functioning as expected. Test the atomizing system, control panel, and ventilation to ensure accuracy before introducing saline solution.

Electrical Safety: Handling Power Connections with Care

Electrical safety is paramount when assembling salt fog test equipment. Always disconnect power before handling electrical components to avoid shocks or short circuits. Use insulated tools and wear rubber-soled footwear to reduce the risk of electrical hazards.

Inspect power cords and connections for signs of wear or damage before plugging in the equipment. Damaged cords should be replaced immediately. Additionally, ensure that the equipment is properly grounded to prevent electrical malfunctions.

For added safety, consider using a surge protector to safeguard your equipment against power fluctuations. Adhering to these precautions will protect both the user and the equipment from potential harm.

For high-quality salt fog test equipment and expert guidance from experienced salt fog test equipment manufacturers, LIB Industry is here to help. Contact us at ellen@lib-industry.com to learn more about our products and services.

References

1. Handbook of Corrosion Testing by ASTM International.

2. "Environmental Testing Equipment: Design and Safety Considerations" by Industrial Testing Journal.

3. "Salt Spray Testing Best Practices" by Corrosion Research Institute.

4. "Electrical Safety in Laboratory Equipment" by National Institute of Standards and Technology.