What are the Application Cases of Benchtop Environmental Chambers in Different Industries?

In today's competitive business landscape, ensuring product reliability and quality is crucial for any industry. A Benchtop Environmental Chamberis a versatile testing equipment that creates controlled environmental conditions to evaluate how products perform under various circumstances. This article will explore the application cases of Benchtop Environmental Chambers in different industries, focusing on the electronics industry, product reliability testing across various sectors, and the specific environmental tests conducted in the food industry.

|

|

Application Cases in the Electronics Industry:

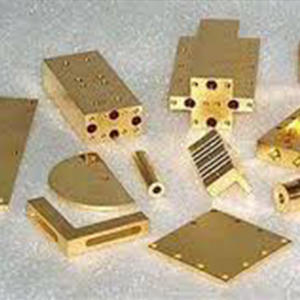

The electronics industry heavily relies on Benchtop Environmental Chambers to assess the performance and durability of electronic components and devices. These chambers simulate extreme temperature conditions, humidity, and other environmental factors to evaluate the reliability and functionality of electronic products. For example, a Benchtop Environmental Chamber can subject circuit boards to high temperatures to assess heat dissipation capabilities or expose electronic components to high humidity to evaluate moisture resistance.

|

|

|

|

Product Reliability Testing in Various Industries:

Benchtop Environmental Chambersfind applications in a wide range of industries beyond electronics. Industries such as automotive, aerospace, pharmaceuticals, and telecommunications utilize these chambers to conduct product reliability testing. In the automotive industry, for instance, Benchtop Environmental Chambers are used to simulate harsh weather conditions, such as extreme temperatures or salt spray, to assess the performance of automotive components and ensure their reliability.

In the aerospace sector, Benchtop Environmental Chambers are employed to recreate the extreme environmental conditions experienced during flight, including rapid changes in temperature, humidity, and pressure. By subjecting components and materials to these conditions, manufacturers can identify potential weaknesses and enhance the reliability of aerospace products.

Similarly, in the pharmaceutical industry, desktopenvironmentaltestchambers play a vital role in testing the stability and integrity of drugs. These chambers can replicate storage conditions, including temperature and humidity variations, to assess the impact on drug efficacy and shelf life.

Environmental Tests in the Food Industry:

The food industry also benefits from the application of mini environmental chamber. These chambers are used to conduct various environmental tests on food products to ensure their safety, quality, and shelf life.

Temperature Testing:

Temperature testing is one of the essential uses of a natural chamber in the food business. During the transportation and storage of perishable goods like dairy products, meat, fruits, and vegetables, it is critical to maintain ideal temperatures. A benchtop natural chamber can imitate different temperature conditions, going from cold capacity to surrounding temperatures, to assess the impact of temperature on item quality, period of usability, and security.

Moistness Testing:

Another important use for an environmental chamber in the food industry is humidity testing. High dampness levels can make dampness development and lead form the development, deterioration, and corruption of food items. Conversely, low moisture levels can cause parchedness, shrinkage, and loss of surface and flavor in food things. A benchtop ecological chamber can recreate fluctuating dampness levels to test the effect of dampness on food items' quality and well-being.

Light Testing:

Light openness can essentially affect the period of usability and the nature of food items. For example, openness to coordinate daylight can cause variety changes, rancidity, and supplement misfortune in food varieties. A benchtop ecological chamber can reproduce different lighting conditions, including regular and fake light, to test the impacts of light openness on food items' quality and security.

Oxygen Testing:

Food safety and quality can be affected by oxygen levels. Oxygen openness can cause oxidation, deterioration, and staining of food things. On the other hand, low oxygen levels can extend the shelf life of products and prevent harmful microorganisms from growing. To evaluate the effects of oxygen exposure on the quality and safety of food products, a benchtop environmental chamber can simulate various oxygen levels.

Testing for Carbon Dioxide:

Carbon dioxide (CO2) is another basic natural component that can influence the timeframe of realistic usability and nature of food items. Raised CO2 levels can hinder the development of unsafe microscopic organisms, parasites, and bugs, and increment the period of usability of items. Be that as it may, over-the-top CO2 levels can likewise cause off-flavors, variety changes, and other quality issues in food things. A benchtop ecological chamber can reproduce different CO2 levels to assess the impact of carbon dioxide openness on food items' quality and well-being.

Tests in the Freezer:

A benchtop environmental chamber can also be used for freezer testing in the food industry. Frozen food things should be put away at fitting temperatures to keep up with their quality and security. A benchtop ecological chamber can mimic outrageous frigid temperatures to test the impact of low temperatures on food items' surface, flavor, and security.

Pressure Testing:

Pressure testing is a fundamental use of a natural chamber for concentrating on the impact of high-height conditions on food items. High-elevation capacity or transportation can influence the bundling and nature of food items. A benchtop ecological chamber can recreate low-pressure conditions to test the presentation of bundling materials and survey the effect of high height on food items' quality and well-being.

Conclusion:

desktopenvironmentaltestchambersare versatile tools used across industries to assess product reliability, performance, and safety. In the electronics industry, these chambers aid in testing electronic components and devices under extreme environmental conditions. Moreover, various industries such as automotive, aerospace, pharmaceuticals, and telecommunications utilize mini environmental chambers for product reliability testing. Lastly, the food industry utilizes these chambers to conduct environmental tests that ensure the safety and quality of food products.

Businesses need to find reliable suppliers of Benchtop Environmental Chambers. LIB Industry is dedicated to providing turn-key solutions for environmental testing, including research, design, production, commissioning, delivery, installation, and training. For more information about Benchtop Environmental Chambers, please contact LIB Industry at info@libtestchamber.com.

References:

1.Smith, J. (2018). Environmental Testing for the Electronics Industry. International Journal of Electronics Testing, 41(2), 156-172.

2.Johnson, A. (2019). Product Reliability Testing: Importance and Methods. Quality Engineering, 27(4), 401-414.

3.Patel, R., & Shah, S. (2020). Environmental Testing in the Food Industry. Food Science and Technology, 35(2), 85-94.

4.Automotive Testing Solutions. (n.d.). Retrieved from [Reference URL]

5.Aerospace Testing Solutions. (n.d.). Retrieved from [Reference URL]

.jpg)