Thermal Shock Environmental Chamber

Lower limit Temperature:-75℃

Upper limit Temperature:+220℃

Temperature Range:-70℃~+220℃

Temperature Recovery Time: Within 5 minutes

Refrigerant: Environmental refrigerant

Touch-screen programmble controller,Ethernet access

- Product Description

Thermal Shock Environmental Chamber Manufacturer & Supplier

The Thermal Shock Environmental Chamber is designed to subject specimens to extreme temperature variations for rigorous analysis and validation.

During the thermal shock test, the material or product is exposed to extreme temperature changes within a short period of time, typically in the range of seconds or minutes. This rapid temperature cycling can cause thermal stress, which can lead to cracking, delamination, or other types of failure.

Technical Specifications:

Model | TS-162 | TS-340 | TS-500 | TS-1000 |

Internal Dimensions (mm) | 300*300*250 | 450*450*360 | 650*650*500 | 850*850*700 |

Overall Dimension (mm) | 1560*870*1545 | 1710*1020*1845 | 1910*1220*2265 | 2110*1420*2665 |

Interior Volume (mm) | 22L | 72L | 211L | 505L |

Loading Capacity | 20kg | 30kg | 50kg | 60kg |

Upper limit Temperature | +220℃ | |||

Heating Time | Ambient ~ + 200℃, within 30 minutes | |||

Lower limit Temperature | -75℃ | |||

Cooling time | Ambient ~ -70℃, within 30 minutes | |||

High Temperature Exposure Range | Ambient +20 ~ +200°C | |||

Low temperature Exposure Range | –65 ~ -5°C | |||

Temperature Fluctuation | ≤±0.5℃ | |||

Temperature Deviation | ≤±3 ℃ | |||

Temperature Recovery Time | Within 5 minutes | |||

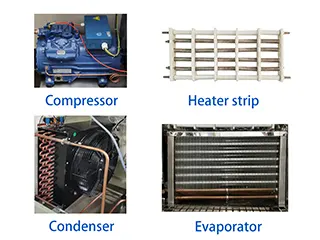

Cooling System | Mechanical compression refrigeration system | |||

Controller | Programmable color LCD touch screen controller, Ethernet connection | |||

Safety Device | Over-temperature protection, Over-current protection; Refrigerant high-pressure protection; Earth leakage protection | |||

Exterior Material | Steel Plate with protective coating | |||

Interior Material | SUS304 stainless steel | |||

Observation Window | Interior lighting, double-layer thermo stability silicone rubber sealing | |||

Standard Configuration | 2 shelves | |||

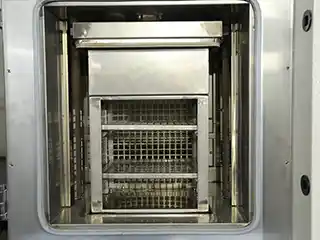

Product Details

|

|

|

| Basket The internal material is 304 stainless steel, mirror surface, rust-proof to high and low temperature and moisture corrosion | Cooling system & Heating system Mechanical compression refrigeration system French TECUMSEH compressor Nickel-chromium alloy heating wire | Castors Install 4 castors for ease moving, and with brakes function. Caster height adjustable. |

|

|

Key Features

LIB industry's Thermal Shock Environmental Chamber is a sophisticated instrument designed for conducting rigorous thermal shock tests on products. This chamber features:

Automated Product Carrier Basket: This system seamlessly moves the product under test between distinct, precisely controlled temperature zones.

Integrated Viewing Windows: Allows for clear observation of the product as it transitions through varying temperature environments.

Customizable Performance Configurations: The chambers are available in multiple setups to cater to specific testing requirements.

Intuitive 8825 Controller: Enhances user interaction with an easy-to-use interface for managing and monitoring the test conditions.

Application Areas

The chamber finds application across diverse industries like aerospace, automotive, electronics, and material sciences, enabling comprehensive testing of products, materials, and components for reliability and performance under extreme conditions.

Certifications

All Thermal Shock Environmental Chamber come with complete test reports and CE certifications.

Xi' An LIB Environmental Simulation Industry manufactures and sells environmental test chambers since 2009, including design, manufacuring, as well as sales and service around the world.

Our complete production line, from cutting, sheet metal, welding, coating, assembly, inspection to calibration, there are rigorously trained technicians working in the industry.The annual ISO9001: 2010 system certification ensures the efficiency and safety of the production process.