Wet Bulb Gauze

Name:Wet Bulb Gauze;

Size: 43x4000mm/reel/box;

Materials: Special "wet ball gauze" made of linen;

Delivery time: 7-10 working days;

Application: Temperature Humidity Test Chamber,;

- Product Description

Wet Bulb Gauze Introduction

Wet Bulb Gauze for humidity test machine, test gauze, humidity measurement gauze Wet ball test gauze is an important part of the humidity test chamber, which is used to test the humidity, which is related to the accuracy of the humidity test parameters of the whole equipment and stability.

Technical Specifications of Temperature Humidity Chamber

Model | TH-500 |

Internal Dimension (mm) | 700*800*900 |

Overall Dimension (mm) | 1200*1340*2020 |

Interior Volume | 500L |

Heat load | 1000W |

Temperature Range | A : -20℃ ~ +150 ℃ B : -40℃ ~ +150 ℃ C: -70℃ ~ +150 ℃ |

Temperature Fluctuation | ± 0.5 ℃ |

Temperature Deviation | ± 2.0 ℃ |

Humidity Range | 20% ~ 98% RH |

Humidity Deviation | ± 2.5% RH |

Cooling Rate | 1 ℃ / min |

Heating Rate | 3 ℃ / min |

Cooling system | Mechanical compression refrigeration system |

Refrigerating unit | French TECUMSEH compressor |

Heating Element | Nichrome heater |

Controller | Programmable color LCD touch screen controller, Ethernet connection |

Water supply system | Automatic water supply, Water purification system |

Humidifier | External isolation, stainless steel surface evaporation humidifier |

Safety Device | Humidifier dry-combustion protection; over-temperature protection; over-current protection; Refrigerant high-pressure protection; Water shortage protection; Earth leakage protection |

Exterior Material | Steel Plate with protective coating |

Interior Material | SUS304 stainless steel |

Thermal Insulation | Polyurethane foam and insulation cotton |

Observation Window | Interior lighting, double-layer thermo stability silicone rubber sealing |

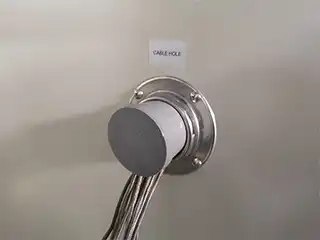

Standard Configuration | 1 Cable hole with plug; 2 shelves |

Product Deatils

|

|

|

| PC Link Ethernet connect to PC for easy operation Match to the local laboratory software USB to download data | Workroom The internal material is 304 stainless steel Rust-proof to high and low temperature and moisture corrosion; | Cable hole The standard inner hole diameter is 50mm/100mm/200mm Soft silicone plug seal; Metal enclosure closed |

|

|

Key Features

Humidity range from 10% RH to 98% RH

Humidity stability and uniformity up to ±1% RH

Capacity ranging from 100L to 2800L

Touchscreen controller for setpoint and data monitoring

Programmable humidity test profiles

Stainless steel interior for corrosion resistance

Low liquid level protection and overhumidity cut-off

Optional temperature control from 0°C to +60°C

Casters and shelves for material handling

Applications

Constant humidity chambers are used for:

Pharma - Conducting drug stability testing in compliance with ICH (International Council for Harmonisation of Technical Requirements for Pharmaceuticals for Human Use) guidelines. The chambers provide a controlled environment for assessing the long-term stability and shelf life of pharmaceutical products under specific humidity conditions, ensuring regulatory compliance and consumer safety.

Food - Testing the storage life of various food products under controlled humidity conditions. By simulating different levels of humidity, these chambers enable food manufacturers to evaluate the impact of moisture on product quality, freshness, and shelf life, aiding in the development of optimal storage and packaging solutions.

Electronics - Assessing the effects of humidity on electronic components and devices, particularly in terms of corrosion and moisture resistance. TH-500 Temperature Relative Humidity Ovens create controlled environments to simulate real-world conditions, allowing manufacturers to validate the reliability and performance of their products under varying humidity levels.

Automotive - Evaluating the moisture resistance of automotive parts and components. These chambers provide a controlled setting for subjecting auto parts to specific humidity levels, enabling manufacturers to assess the impact of moisture on materials, coatings, and electronic systems, ensuring the durability and longevity of automotive products.

Packaging - Analyzing the performance of packaging materials and containers under high humidity conditions. The chambers facilitate accelerated aging tests and quality assessments of packaging materials, helping manufacturers ensure the integrity and effectiveness of their packaging solutions in humid environments.

.webp)