Temperature cycling chambers, moreover known as thermal cycling chambers, are crucial devices in different businesses for testing the versatility and execution of items beneath extraordinary temperature conditions. These advanced gadgets mimic real-world natural scenarios, subjecting materials and components to quick temperature vacillations. Understanding the temperature ranges these chambers can accomplish is pivotal for producers, analysts, and quality control experts looking for to guarantee item unwavering quality and toughness.

The Fundamentals of Temperature Cycling Chambers

Defining Temperature Cycling Chambers

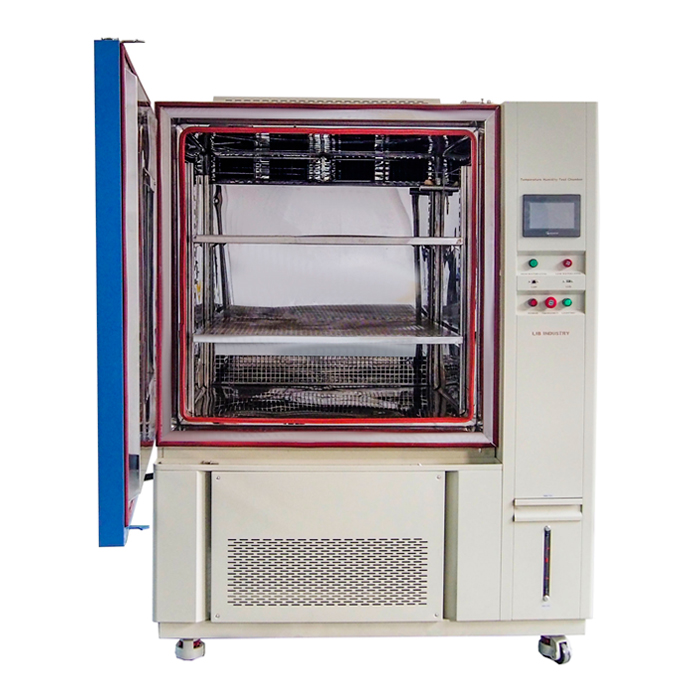

Temperature cycling chambers are specialized environmental testing equipment designed to expose materials and products to controlled temperature variations. These chambers create cyclic temperature changes, allowing researchers and engineers to evaluate how items respond to thermal stress over time.

Key Components of Thermal Cycling Chambers

The core elements of a temperature cycling chamber include a robust insulated enclosure, precise temperature control systems, and powerful heating and cooling mechanisms. Advanced models may incorporate additional features such as humidity control, programmable cycles, and data logging capabilities.

Applications Across Industries

From electronics and automotive to aerospace and pharmaceuticals, thermal cycling chambers find applications in numerous sectors. They play a pivotal role in product development, quality assurance, and regulatory compliance testing, ensuring that items can withstand the thermal challenges they may encounter during their lifecycle.

Exploring Temperature Ranges in Cycling Chambers

Standard Temperature Ranges

Most commercial temperature cycling chambers offer a standard temperature range of -40 °C to +150 °C (-40 °F to +302 °F). This range is sufficient for many common testing protocols and covers the environmental conditions that many products are likely to encounter during normal use and storage.

Extended Range Capabilities

For more demanding applications, specialized temperature cycling chambers can achieve even more extreme temperatures. Some high-performance models can reach as low as -80°C (-112°F) or as high as +300°C (+572°F). These extended ranges are particularly valuable for testing components destined for use in harsh environments, such as space exploration or deep-sea applications.

Rapid Temperature Change Rates

Beyond the absolute temperature limits, the rate at which a chamber can transition between temperature extremes is a critical factor. Advanced thermal cycling chambers can achieve temperature change rates of up to 15°C per minute or more, allowing for accelerated stress testing and more efficient test cycles.

Factors Influencing Temperature Range Performance

Chamber Size and Design

The physical dimensions and construction of a temperature cycling chamber significantly impact its performance. Larger chambers may have more thermal inertia, affecting the speed of temperature changes, while smaller chambers can often achieve more rapid cycling. The quality of insulation and the efficiency of air circulation systems also play crucial roles in maintaining precise temperature control.

Cooling Technology

The type of cooling system employed in a thermal cycling chamber is a key determinant of its low-temperature capabilities. While many chambers use mechanical refrigeration systems, those requiring extremely low temperatures may utilize liquid nitrogen cooling. The choice of cooling technology affects not only the minimum achievable temperature but also the chamber's energy efficiency and operating costs.

Heating Elements

The heating system's power and design influence the maximum temperature and the rate of temperature increase. Advanced chambers often use a combination of convection and radiation heating to ensure uniform temperature distribution and rapid warming cycles. They are strategically positioned to eliminate cold spots and provide consistent heat across the entire testing volume, which is crucial for obtaining accurate and reproducible test results in various applications such as electronics, automotive, and aerospace industries.

Selecting the Right Temperature Cycling Chamber

Assessing Testing Requirements

When choosing a temperature cycling chamber, it's essential to carefully evaluate the specific testing needs of your products or materials. Consider not only the temperature extremes required but also the frequency and duration of cycles, as well as any additional environmental factors such as humidity control. Consider the need for any specialized features like vibration simulation during temperature cycling, which could be relevant for products used in transportation or mobile applications.

Considering Future Needs

While it may be tempting to opt for a chamber that meets only current testing requirements, investing in a more versatile unit with extended temperature ranges can provide long-term benefits. As product designs evolve and testing standards become more stringent, having a chamber with broader capabilities can save time and resources in the future.

Evaluating Chamber Performance Metrics

Beyond raw temperature specifications, it's important to examine other performance metrics when selecting a thermal cycling chamber. These may include temperature uniformity throughout the chamber, recovery time after door openings, and the precision of temperature control. Reliable manufacturers provide detailed performance data to help users make informed decisions.

Conclusion

Temperature cycling chambers are remarkable pieces of equipment capable of achieving a wide range of temperatures to meet diverse testing needs. From standard ranges of -40°C to +150°C to extreme capabilities reaching -80 °C or +300 °C, these chambers play a crucial role in ensuring product quality and reliability across industries. By understanding the factors that influence temperature range performance and carefully assessing specific testing requirements, organizations can select the ideal thermal cycling chamber to support their product development and quality assurance processes.

Contact Us

For expert guidance on selecting the perfect temperature cycling chamber for your unique testing needs, contact LIB Industry. Our team of specialists is ready to provide comprehensive solutions tailored to your specifications. Reach out to us at info@libtestchamber.com to explore how our advanced thermal cycling chambers can elevate your testing capabilities and ensure the utmost reliability of your products.