What is temperature cycle test chamber?

What is a Temperature Cycle Test Chamber?

Temperature test chambers are fundamental devices in the realm of natural testing. They reenact fluctuating temperature conditions to test the sturdiness and unwavering quality of materials, parts, and items. Car, hardware, aviation, and drugs all depend on this testing strategy to guarantee that their items can endure outrageous temperatures and temperature vacillations.

Understanding Temperature Cycle Test Chambers

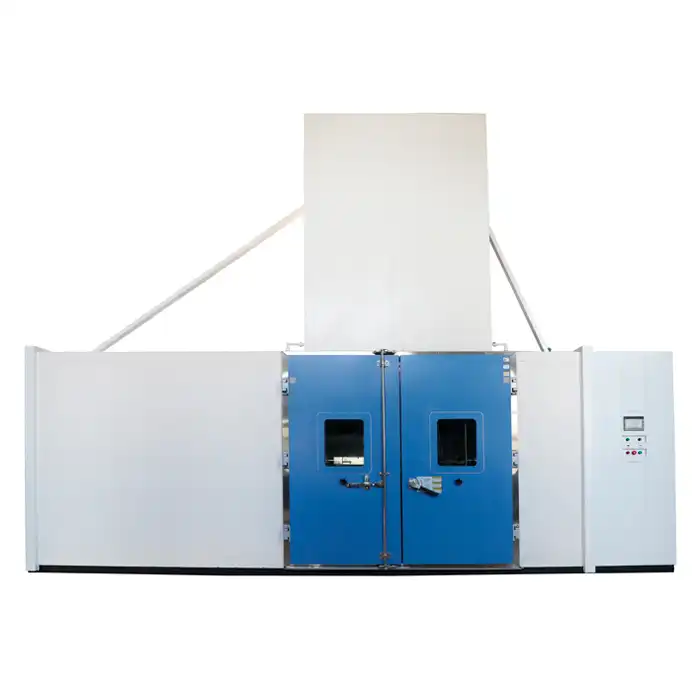

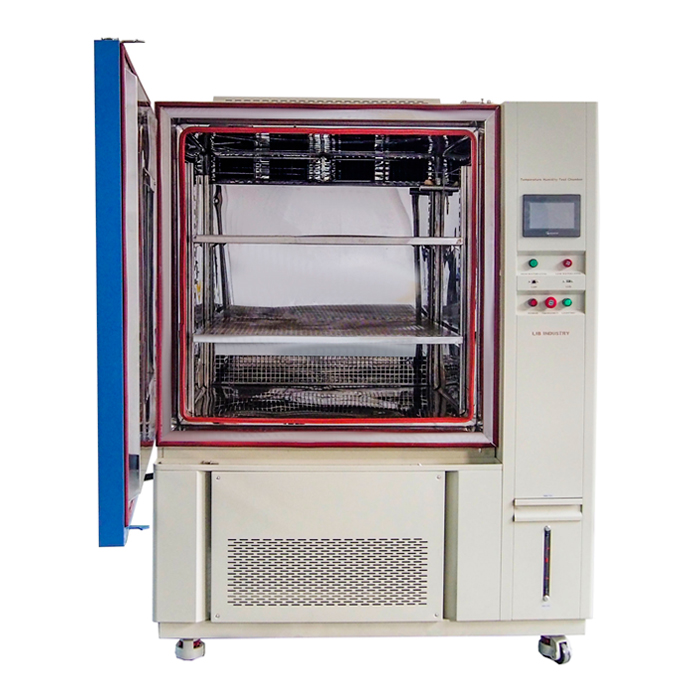

A temperature test chamber, otherwise called a warm cycle chamber, is a specific piece of hardware intended to uncover items and materials to fast temperature changes. The essential objective is to evaluate the way in which these things answer warm pressure, recognizing potential shortcomings that could prompt disappointments in true circumstances.A specialized apparatus made to expose products and materials to rapid temperature changes is known as a temperature cycle test chamber or thermal cycle chamber. Its primary objective is to examine these items' responses to thermal stress and identify potential flaws that could cause failures in actual conditions. By presenting items to rotating high and low temperatures, producers can recreate the cruel ecological circumstances they could experience during use. The evaluation of durability, performance in extreme temperatures, and overall dependability are aided by this testing procedure. It empowers proactive distinguishing proof and correction of configuration defects or material deficiencies before items are delivered to advertise, consequently improving item quality and consumer loyalty.

These chambers operate by cycling between high and low temperatures in a controlled manner. The temperature ranges and cycle durations can be customized to meet specific testing requirements. For instance, a test might involve cycling between -40°C and +85°C, with each cycle lasting a predetermined amount of time. By subjecting products to these conditions, manufacturers can gain insights into their thermal performance and make necessary improvements.These chambers work by cycling among high and low temperatures in a controlled way. The temperature ranges and cycle spans can be tweaked to meet explicit testing prerequisites. For instance, an ordinary test might include cycling between limits like - 40°C and +85°C, with each cycle enduring a predefined span. This controlled openness permits makers to assess how items endure warm pressure, giving important experiences into their warm presentation and empowering fundamental enhancements to be made before definite creation and market discharge.

Key Features and Benefits

1. Versatility and Precision: Temperature test chambers are incredibly versatile, accommodating a wide range of products and materials. They offer exact command over temperature settings, guaranteeing predictable and precise testing conditions. This accuracy is essential for getting solid and reproducible outcomes, which are critical for item advancement and quality affirmation.

2. Enhanced Product Reliability: By simulating real-world temperature fluctuations, these chambers help identify potential issues that could affect product reliability. For instance, electronic parts might encounter warm extension and constriction, prompting patch joint disappointments. By distinguishing these issues from the get-go in the advancement cycle, makers can make plan upgrades to improve item sturdiness and life span.

3. Compliance with Industry Standards: Many industries have stringent standards for product testing, and temperature test chambers play a key role in meeting these requirements. For instance, the automotive industry relies on these chambers to ensure that components can withstand the temperature variations experienced during vehicle operation. Compliance with these standards not only ensures product safety but also builds trust with customers and regulatory bodies.

Applications in Various Industries

1. Automotive Industry: In the automotive industry, temperature cycle testing is used to evaluate the performance of components such as engines, transmissions, and electronic systems. These tests ensure that vehicles can operate reliably in extreme temperatures, from freezing winters to scorching summers. For example, engine components are subjected to thermal cycling to assess their resistance to thermal fatigue and potential failure.

2. Electronics and Semiconductor Industry: The electronics and semiconductor industry relies heavily on temperature cycle test chambers to ensure the reliability of integrated circuits, printed circuit boards (PCBs), and other electronic components. These tests help identify potential issues such as thermal expansion and contraction, which can lead to solder joint failures and reduced product lifespan.

3. Aerospace Industry: In the aerospace industry, temperature cycle testing is critical for evaluating the performance of materials and components used in aircraft and spacecraft. These tests simulate the extreme temperature variations experienced during flight, ensuring that components can withstand the harsh conditions of the aerospace environment. For example, turbine blades are subjected to thermal cycling to assess their resistance to thermal stress and potential cracking.

4. Pharmaceutical Industry: The pharmaceutical industry uses temperature cycle test chambers to ensure the stability and efficacy of drugs and vaccines. These tests help determine the impact of temperature fluctuations on the chemical composition and effectiveness of pharmaceutical products. For instance, vaccines are subjected to thermal cycling to ensure their potency is maintained throughout their shelf life.

Conclusion

Temperature test chambers are indispensable tools for industries that require reliable and durable products. By simulating real-world temperature variations, these chambers help manufacturers identify potential issues early in the development process, ensuring that products can withstand extreme conditions. Whether in the automotive, electronics, aerospace, or pharmaceutical industry, temperature test chambers play a crucial role in enhancing product reliability and compliance with industry standards. Investing in temperature cycle testing not only improves product quality but also builds trust with customers and regulatory bodies, ultimately contributing to long-term success.Temperature cycle test chambers are essential tools for all industries that place an emphasis on products that are dependable and long-lasting. By precisely reenacting true temperature varieties, these chambers empower makers to identify potential issues from the get-go in the improvement cycle. This proactive methodology guarantees that items can endure outrageous circumstances prior to arriving at the market. Whether in auto, hardware, aviation, or drug areas, temperature cycle test chambers assume an essential part in upgrading item dependability and satisfying severe industry guidelines. Putting resources into temperature cycle testing upgrades item quality as well as cultivates entrust with clients and administrative bodies. Eventually, this obligation to thorough testing adds to long haul accomplishment by diminishing guarantee claims, further developing brand notoriety, and guaranteeing consistence with wellbeing and execution prerequisites.

For more information on temperature cycle test chambers and how they can benefit your industry, contact us at info@libtestchamber.com.