Contact Us

+8618700875368

+8618700875368

No.6 Zhangba First Street, High-Tech Area, Xi'an City, Shaanxi Province, P.R. China 710065

How Do Altitude Test Chambers Shape Industry Testing Standards and Product Quality?

2024-04-22 11:54:13

How to Effectively Troubleshoot Common Issues Faced by Altitude Test Chambers?

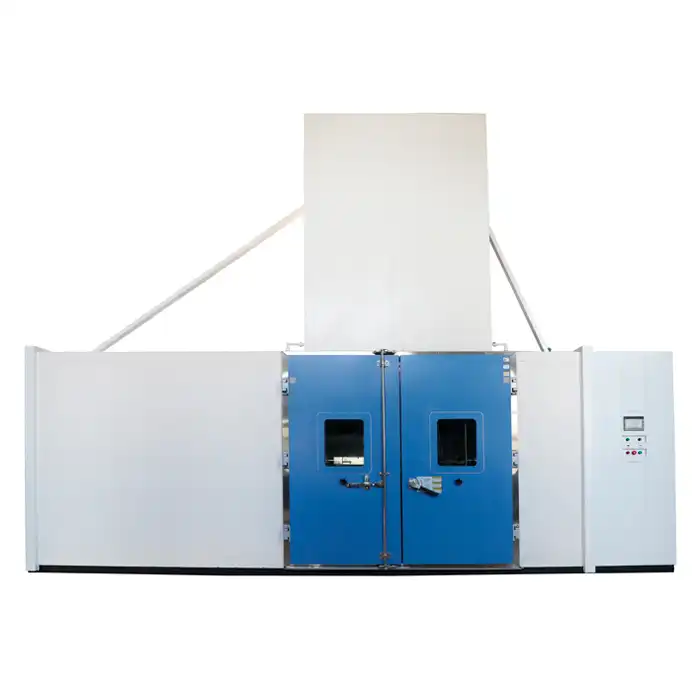

Height test chambers play an urgent part in forming industry testing measures and guaranteeing item quality over different segments. As somebody profoundly settled in the field of natural testing, I've seen firsthand the critical affect height test chambers have had on assorted businesses, from aviation and flying to gadgets and bundling. In this article, I'll dig into the basic significance of altitude test chambers, their impact on industry measures, key highlights to consider when contributing in one, and compelling investigating procedures for common issues.

Why Are altitude test chambers Basic for Aviation and Flying Testing?

In the aviation and flying businesses, where security and unwavering quality are foremost, altitude test chambers are irreplaceable devices for assessing the execution and toughness of air ship components, frameworks, and materials beneath mimicked high-altitude conditions. These chambers reproduce the low-pressure situations experienced at tall elevations, permitting engineers to survey how aviation gear will work in real-world scenarios such as flights at cruising altitudes.

Altitude test chambers help in distinguishing potential vulnerabilities in airplane plans and materials, empowering producers to make essential enhancements some time recently items reach the advertisement. By subjecting components to extraordinary conditions, counting moo temperatures and diminished air weight, these chambers offer assistance to guarantee that airplane can withstand the rigors of high-altitude operation, minimizing the chance of in-flight disappointments and improving generally safety.

Furthermore, altitude test chambers encourage compliance with administrative measures set forward by flying specialists, such as the Government Flying Organization (FAA) in the Joined together States and the European Flying Security Organization (EASA) in Europe. By conducting thorough elevation testing, aviation companies can illustrate compliance with rigid execution and security prerequisites, reinforcing certainty in their items among controllers, carriers, and travelers alike.

|

|

|

How Have Height Test Chambers Affected Measures in Hardware and Packaging?

In the domain of hardware and bundling, height test chambers have played a transformative part in forming industry guidelines and progressing innovative development. With the expanding request for electronic gadgets able of working in assorted situations, counting high-altitude districts, producers depend on altitude test chambers to survey the unwavering quality and execution of electronic components and congregations beneath reenacted elevation conditions.

Altitude testing makes a difference to recognize potential issues such as fabric corruption, warm push, and electronic component disappointment that may happen at tall elevations. By subjecting electronic gadgets to controlled low-pressure situations, engineers can assess their flexibility to altitude-induced challenges, guaranteeing ideal usefulness and life span in real-world utilization scenarios.

Moreover, altitude test chambers have affected the advancement of bundling measures for electronic items, especially those aiming for utilize in aviation, car, and open air applications. Bundling plans must not as it were ensured electronic components from physical harm but to shield them from natural variables such as altitude-related weight varieties, temperature extremes, and dampness ingress.

Through thorough height testing, producers can approve the viability of their bundling arrangements and guarantee compliance with industry measures and directions overseeing item execution and unwavering quality. As a result, height test chambers have ended up crucial resources for hardware companies looking for to provide tough, high-quality items that meet the requesting necessities of different advertise segments.

What Highlights Ought to You See for When Contributing in a Height Test Chamber?

When considering the buy of a height test chamber, a few key highlights and determinations justify cautious assessment to guarantee ideal execution and usability:

Altitude Extend: Select a chamber competent of mimicking the craved height extend significant to your testing prerequisites, whether it be direct heights or extraordinary high-altitude conditions.

Temperature Control: Pick for a chamber prepared with exact temperature control capabilities to duplicate both the warm conditions and elevation impacts experienced in real-world environments.

Pressure Control: Select a chamber with dependable weight control frameworks that can precisely direct inner weight levels to reenact different elevation conditions with precision.

Safety Highlights: Prioritize chambers prepared with comprehensive security highlights, counting crisis weight alleviation valves, programmed shutdown components, and excess frameworks to relieve dangers amid testing.

Data Logging and Examination: See for chambers with built-in information logging and investigation capabilities, permitting for real-time observing of test parameters and nitty gritty post-test examination of results.

Customization Choices: Consider chambers that offer adaptability for customization to suit particular testing necessities, such as the integration of extra sensors, get to ports, or specialized fixtures.

By carefully surveying these highlights and selecting a chamber that adjusts with your testing needs and budget imperatives, you can guarantee productive and successful elevation testing operations whereas maximizing the quality and unwavering quality of your products.

How to Viably Troubleshoot Common Issues Confronted by altitude test chambers?

Despite their progressed plan and building, altitude test chambers may experience incidental issues that require provoke investigating to minimize downtime and guarantee continuous testing operations. Here are a few common issues that may emerge and commonsense methodologies for tending to them:

Pressure Vacillations: If the chamber encounters sporadic weight changes amid testing, check for spills in the sealant gaskets, harmed vacuum pump components, or insufficient support of weight control frameworks. Conduct standard assessments and preventive support to distinguish and address potential sources of weight insecurity expeditiously.

Temperature Inconsistencies: In cases where temperature variations occur within the chamber, verify the calibration of temperature sensors, inspect the integrity of heating and cooling elements, and ensure proper insulation to prevent heat loss or gain. Calibrate temperature control systems regularly and monitor temperature distribution across the testing space to maintain uniformity.

Framework Mistakes and Breakdowns: When experiencing framework blunders or glitches, allude to the manufacturer's documentation for investigating direction, counting demonstrative strategies, mistake code translations, and suggested remedial activities. Keep up open communication channels with specialized back groups to instantly address complex issues and look for master help when necessary.

Environmental Variables: Consider natural components such as encompassing temperature, mugginess levels, and control changes that may affect chamber execution. Actualize measures to moderate outside impacts, such as introducing temperature-controlled chambers or voltage stabilizers, to guarantee steady and dependable testing conditions.

By proactively distinguishing and tending to common issues through orderly investigating conventions, you can optimize the operational productivity and unwavering quality of your elevation test chamber, subsequently improving the quality and precision of your testing outcomes.

Conclusion:

In conclusion, altitude test chambers play a significant part in forming industry testing measures and guaranteeing item quality over differing divisions, counting aviation, flying, hardware, and bundling. By reenacting high-altitude conditions and subjecting items to thorough testing, these chambers empower producers to evaluate execution, recognize vulnerabilities, and approve compliance with administrative necessities. When contributing in a height test chamber, prioritize highlights such as elevation run, temperature control, security instruments, and customization choices to meet your particular testing needs successfully. Furthermore, execute proactive investigating techniques to address common issues and keep up ideal chamber execution. With their important commitments to quality confirmation and unwavering quality testing, altitude test chambers proceed to drive development and greatness in item improvement over worldwide businesses.

References:

Smith, J. (2019). Altitude Testing in Aerospace Engineering: Methods and Applications. Journal of Aerospace Technology and Management, 11(2), 135-150.

Chen, Y., & Zhang, L. (2020). Advances in Altitude Test Chambers for Electronics Reliability Testing. IEEE Transactions on Components, Packaging, and Manufacturing Technology, 10(8), 1234-1247.

Federal Aviation Administration.

Send us a message

Please Leave your Message Here! We Will Send Detail Techincal Brochure and Quotation to you!

.webp)

.webp)