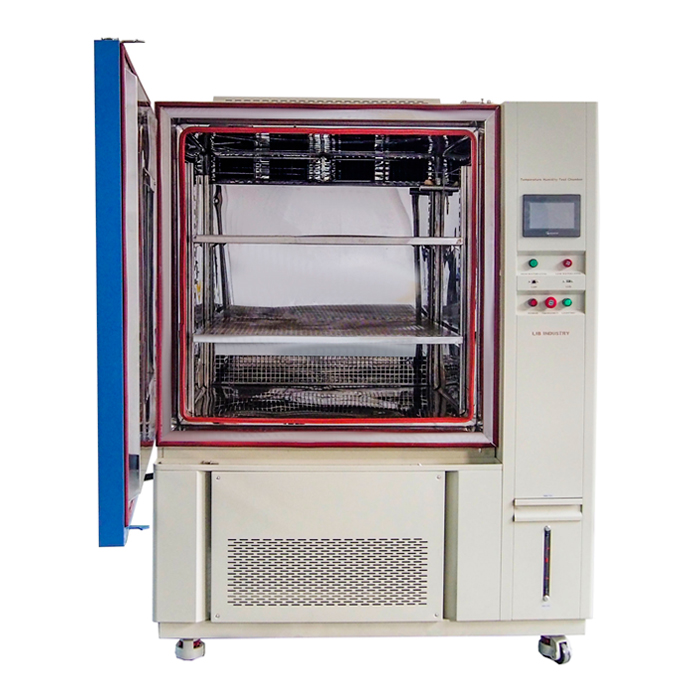

Temperature Test Chamber

Lowest Temperature: -20℃/-40℃/-60℃/-120℃;

Temperature Range:-120℃~+150 ℃;

Humidity Range:20% ~ 98% RH;

Temperature and Humidity condition

Touch-screen programmble controller,Ethernet access

Safety options for testing lithium-ion batteries

- Product Description

Temperature Test Chamber Manufacturer & Supplier

A temperature test chamber, also known as an environmental chamber or thermal chamber, is a specialized piece of equipment designed to test the performance and reliability of products under various temperature conditions.

LIB industry's chambers are extensively used in various industries, including electronics, automotive, aerospace, and pharmaceuticals. They play a critical role in evaluating product performance, validating design specifications, and simulating real-world conditions during product development and quality control processes.

Technical Specifications

Model | T-100 | T-225 | T-500 | T-800 | T-1000 |

Internal Dimension (mm) | 400*500*500 | 500*600*750 | 700*800*900 | 800*1000*1000 | 1000*1000*1000 |

Overall Dimension (mm) | 900*1050*1620 | 1000*1140*1870 | 1200*1340*2020 | 1300*1540*2120 | 1500*1540*2140 |

Interior Volume | 100L | 225L | 500L | 800L | 1000L |

Heat load | 1000W | ||||

Temperature Range | A : -20℃ ~ +150 ℃ B : -40℃ ~ +150 ℃ C: -70℃ ~ +150 ℃ | ||||

Temperature Fluctuation | ± 0.5 ℃ | ||||

Temperature Deviation | ± 2.0 ℃ | ||||

Cooling Rate | 3 ℃ / min | ||||

Heating Rate | 1 ℃ / min | ||||

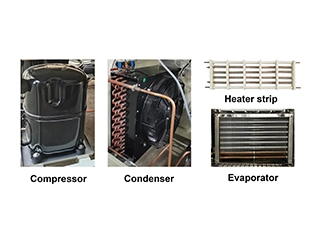

Cooling system | Mechanical compression refrigeration system | ||||

Refrigerating unit | French TECUMSEH compressor | ||||

Heating Element | Nichrome heater | ||||

Controller | Programmable color LCD touch screen controller Ethernet connection, PC Link | ||||

Temperature Sensor | PTR Platinum Resistance PT100Ω/MV A-class | ||||

Air Circulation | Centrifugal wind fan | ||||

Safety Device | Over-temperature Protection; Over-current Protection; Refrigerant High-Pressure Protection; Earth leakage Protection | ||||

Exterior Material | Steel Plate with protective coating | ||||

Interior Material | SUS304 stainless steel | ||||

Thermal Insulation | Polyurethane foam and insulation cotton | ||||

Observation Window | Interior lighting, double-layer thermo stability silicone rubber sealing | ||||

Standard Configuration | 1 Cable hole (Φ 50,) with plug; 2 shelves | ||||

Product Details

|

|

|

Security Settings Emergency stop button SMS alarm Fault warning devic | Cable hole The standard inner hole diameter is 50mm/100mm/200mm Soft silicone plug seal; Metal enclosure closed | Cooling system Mechanical compression refrigeration system French TECUMSEH compressor Environmentally friendly refrigerant |

|

|

Temperature Test Chamber Key Features

Temperature range from -70°C to +180°C

Excellent temperature uniformity ±0.5°C

Programmable temperature ramp rates

Touchscreen controller for setpoint programming

Humidity control from 10% to 98% RH (optional)

Adjustable shelves, interior lighting

Compact, space-saving footprint

Applications

Temperature test chamber have wide applications across industries:

Aerospace - Testing avionics, engines, structural components, and advanced materials at extreme high and low temperatures to evaluate performance and durability under flight conditions.

Automotive - Conducting thermal shock, thermal cycling and soak testing of mechanical auto parts like power steering and braking systems, electrical wiring, and electronic engine control units for operation at extreme temperatures.

Electronics - Thermal testing of PCBs from high to low temperatures in seconds. Thermal cycling between temperature limits for component stress screening.

Pharmaceutical - Stability and shelf-life testing of pharmaceutical products like drugs, injections, ointments, tablets according to ICH/WHO guidelines for long-term and accelerated conditions.

Food - Freezing and thawing studies to determine texture changes in frozen foods. Refrigerated storage testing to determine shelf-life. Sterilization of packaged foods using high heat.

Packaging - Temperature Test Chamber test the durability and strength of packaging materials like plastic, glass, metal and paperboard at freezing, elevated and cycling conditions to simulate shipping and storage environments.

After-sales Support

We provide commissioning, onsite validation and comprehensive training by experienced engineers to ensure optimal performance. For any technical queries, customers can contact our service desk for troubleshooting and repairs. We offer maintenance contracts for preventive servicing at regular intervals.

.webp)