What is the purpose of a thermal vacuum chamber?

What is the Purpose of a Thermal Vacuum Chamber?

In businesses where accuracy and unwavering quality are basic, warm vacuum chambers serve a crucial job by reenacting the outrageous circumstances tracked down in space or other brutal conditions. These chambers replicate the vacuum and extreme temperatures of space or deep-sea conditions by creating a controlled environment devoid of air pressure and precisely controlled temperatures.

Putting equipment, components, or materials under rapid temperature and vacuum changes is the primary function of a thermal vacuum chamber, especially one that can change quickly. This capacity permits makers to assess how their items perform under these difficult conditions. In these chambers, aerospace components like satellites, instruments for spacecraft, and thermal insulation materials are put through rigorous testing to make sure they can withstand the harsh conditions of space, like extreme temperatures that can change from scorching hot to freezing cold in a matter of seconds.

Because it speeds up the testing process and provides quicker insights into product performance under dynamic thermal conditions, the fast change feature is especially useful. Engineers can quickly make necessary design enhancements thanks to this capability, which is essential for identifying potential flaws or vulnerabilities early in the development cycle.

Thermal vacuum chambers that can change quickly also make research and development efforts in a variety of industries more effective. They work with iterative testing and approval of models, guaranteeing that eventual outcomes satisfy tough execution guidelines and administrative prerequisites. In high-stakes industries, this advanced testing technology not only increases product reliability but also speeds up time to market, ultimately supporting innovation and competitive advantage.

In conclusion, testing equipment and materials' resilience and replicating extreme environmental conditions require the use of fast-changing thermal vacuum chambers. Their significance in advancing technology and meeting the demands of modern industries is highlighted by their role in ensuring product durability and performance in challenging environments.

Understanding Thermal Vacuum Chambers

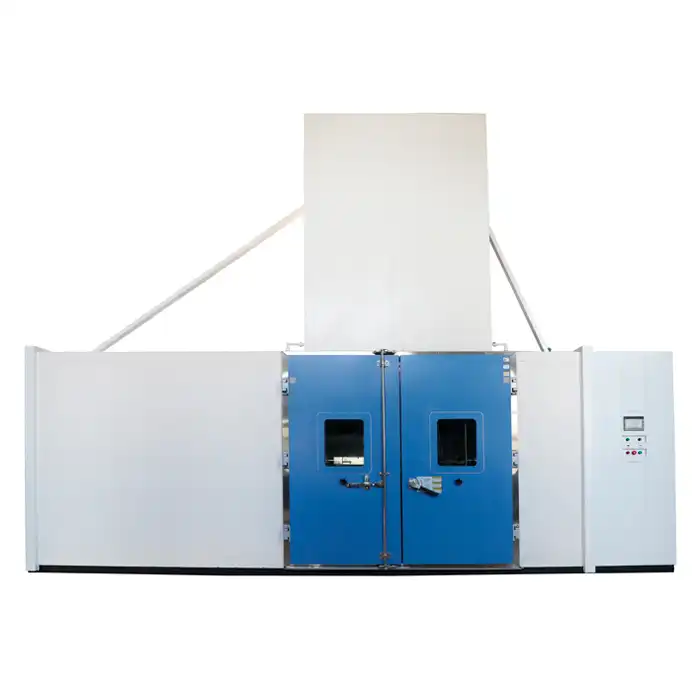

Thermal vacuum chambers, also known as environmental test chambers, are specialized enclosures that are necessary for subjecting items to precisely controlled temperature and pressure conditions similar to those found in harsh environments like space or other places. Before being used in real-world situations, these chambers are crucial for testing a variety of products' durability and performance.

Thermal vacuum chambers mimic the harsh conditions of space, including rapid transitions from extreme heat to cold, by creating a vacuum and regulating temperature gradients. This testing ability is essential for assessing how materials, parts, and whole frameworks answer such stressors, guaranteeing they meet severe unwavering quality and wellbeing principles.

Thermal vacuum chambers are heavily used by aerospace, defense, and automotive industries to verify the durability of satellites, spacecraft components, thermal protection systems, and delicate electronics. For example, satellites should get through outrageous temperature variances and vacuum conditions in space, making pre-flight testing in these chambers fundamental to check their usefulness and survivability.

Additionally, life cycle simulations and accelerated aging tests are made possible by thermal vacuum chambers, allowing manufacturers to forecast product performance over time. This proactive methodology distinguishes potential shortcomings from the get-go in the plan stage, empowering iterative enhancements and guaranteeing items endure the afflictions of their expected surroundings.

In conclusion, the use of thermal vacuum chambers is absolutely necessary in order to guarantee the robustness and dependability of products that are intended for use in extreme environments like space. Innovation, quality control, and ultimately the successful implementation of cutting-edge technologies across a wide range of industries are all aided by their precise ability to replicate challenging conditions.

The Role of Fast Change Capability

The ability of modern thermal vacuum chambers to achieve rapid temperature transitions is one of their remarkable advancements. In the past, testing procedures were hampered by the time it took to switch between extreme temperatures. However, fast change thermal chambers have revolutionized this aspect of testing thanks to recent technological advancements. These chambers can now quickly and definitively adjust temperatures, reproducing fast moves experienced in space or other testing conditions. This improvement speeds up testing timetables fundamentally, empowering producers to direct more cycles and refine plans productively. Consequently, fast change thermal chambers ensure robust performance in extreme conditions and play a crucial role in extending product development cycles in aerospace, automotive, and electronics industries.

Fast change thermal chambers are equipped with innovative heating and cooling systems that enable them to quickly alter internal temperatures. This capability is invaluable for testing scenarios where rapid temperature fluctuations are critical to evaluating a product’s performance accurately. For instance, spacecraft components often experience sudden shifts in temperature as they move between sunlight and shadow in space. Testing these components under similar conditions ensures their reliability and durability in actual missions.

Applications and Benefits

The applications of fast change thermal chambers are diverse and span across various industries:

- Aerospace: Testing satellites, spacecraft components, and materials that will be exposed to the vacuum and temperature variations of space.

- Electronics: Evaluating electronics and semiconductor devices that need to function flawlessly under extreme temperature conditions.

- Automotive: Testing vehicle components to ensure they can withstand harsh environmental conditions encountered during operation.

By subjecting products to such rigorous conditions in a controlled environment, engineers can identify potential weaknesses early in the development cycle. This proactive approach helps in refining designs, improving product reliability, and ultimately reducing the risk of failure in the field.

Conclusion

In conclusion, the purpose of a thermal vacuum chamber, particularly one equipped with fast change capabilities, is to replicate and assess how products will perform under extreme environmental conditions. By simulating these conditions accurately, manufacturers and researchers can ensure that their products meet stringent quality standards and are capable of withstanding the challenges of real-world applications.

Whether it's testing the resilience of a satellite's communication system or ensuring the reliability of a smartphone in Arctic temperatures, the role of these chambers is indispensable. They not only validate the durability of products but also contribute significantly to advancing technology and innovation across various industries.

In essence, investing in a fast change thermal chamber isn't just about meeting regulatory requirements; it's about fostering confidence in product performance and pushing the boundaries of what's possible in environmental testing. For more insights into how these chambers can benefit your specific testing needs, feel free to contact us.

By delivering reliable testing solutions, we at LIB Industries remain committed to supporting your journey towards excellence in product development and performance assurance.