Hot Cold Chamber

Lowest Temperature: -20℃/-40℃/-60℃/-70℃/-86℃;

Temperature Range:-86℃~+150 ℃;

Humidity Range:20% ~ 98% RH;

Safety options for testing lithium-ion batteries

Built-in lighting for observing the test

Water purification and recirculation system

- Product Description

Hot Cold Chamber Manufacturer & Supplier

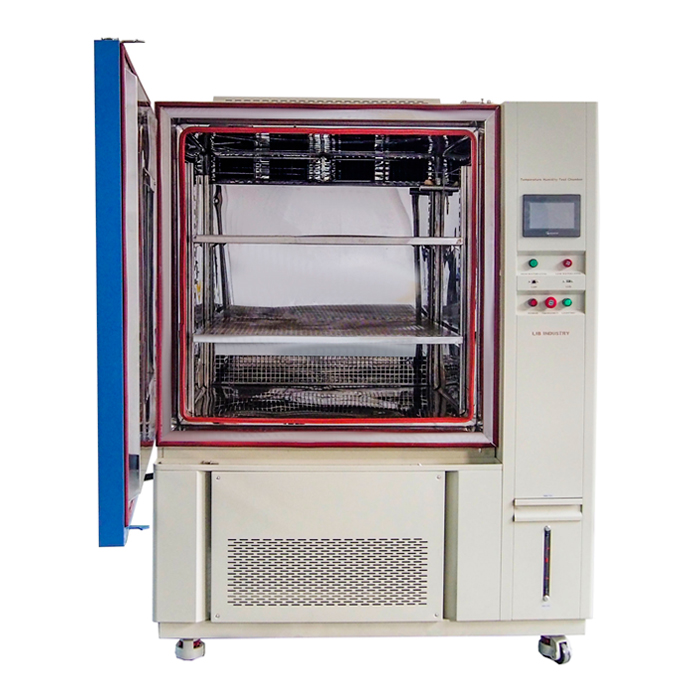

The hot cold chamber, is an advanced environmental test system designed to recreate extreme temperature changes for product testing. It consists of a well-insulated chamber, heating and refrigeration systems, airflow fans and a digital temperature controller. The hot cold test chamber provides alternating hot and cold temperature cycles to evaluate the thermal resistance of components, materials and finished products.

Technical Specifications

Model | T-100 | T-225 | T-500 | T-800 | T-1000 |

Internal Dimension (mm) | 400*500*500 | 500*600*750 | 700*800*900 | 800*1000*1000 | 1000*1000*1000 |

Overall Dimension (mm) | 900*1050*1620 | 1000*1140*1870 | 1200*1340*2020 | 1300*1540*2120 | 1500*1540*2140 |

Interior Volume | 100L | 225L | 500L | 800L | 1000L |

Heat load | 1000W | ||||

Temperature Range | A : -20℃ ~ +150 ℃ B : -40℃ ~ +150 ℃ C: -70℃ ~ +150 ℃ | ||||

Temperature Fluctuation | ± 0.5 ℃ | ||||

Temperature Deviation | ± 2.0 ℃ | ||||

Cooling Rate | 3 ℃ / min | ||||

Heating Rate | 1 ℃ / min | ||||

Cooling system | Mechanical compression refrigeration system | ||||

Refrigerating unit | French TECUMSEH compressor | ||||

Heating Element | Nichrome heater | ||||

Controller | Programmable color LCD touch screen controller Ethernet connection, PC Link | ||||

Temperature Sensor | PTR Platinum Resistance PT100Ω/MV A-class | ||||

Air Circulation | Centrifugal wind fan | ||||

Safety Device | Over-temperature Protection; Over-current Protection; Refrigerant High-Pressure Protection; Earth leakage Protection | ||||

Exterior Material | Steel Plate with protective coating | ||||

Interior Material | SUS304 stainless steel | ||||

Thermal Insulation | Polyurethane foam and insulation cotton | ||||

Observation Window | Interior lighting, double-layer thermo stability silicone rubber sealing | ||||

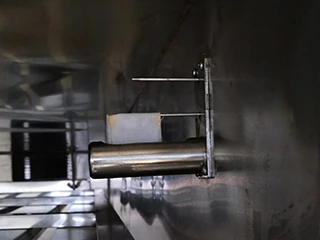

Standard Configuration | 1 Cable hole (Φ 50,) with plug; 2 shelves | ||||

Product Details

|

|

|

| Cable hole A standard test hole with plugs The standard inner hole diameter is 50mm/100mm/200mm | Temperature sensor PT-100 Class A sensor, real-time accurate detection and display of temperature changes at 0.001 degrees. | Air circulation The air is uniformly distributed through the air outlet Air circulates evenly throughout the workroom |

|

|

Applications

LIB industry's hot cold test chamber has wide applications across industries:

Automotive: Hot Cold Chamber is used for testing electronic and mechanical auto parts under alternating temperature extremes, simulating real-world conditions to assess their performance and durability in extreme temperature variations.

Aerospace: Hot-cold chambers are employed for evaluating the thermal shock resistance of avionics and aerospace alloys, ensuring their reliability and functionality under rapid temperature changes experienced during flight and in space.

Electronics: These chambers are utilized for assessing the thermal withstand of printed circuit boards (PCBs), semiconductors, and other electronic components, ensuring their stability and performance under fluctuating temperature conditions.

Defense: Hot-cold chambers are crucial for testing ammunition stability through rapid temperature transitions, ensuring the integrity and effectiveness of ammunition under varying environmental conditions.

Pharmaceuticals: Thermal shock testing is conducted using hot-cold chambers to assess the resilience of glass vials, ampoules, and packaging materials, ensuring their ability to withstand temperature variations during storage and transportation.

Food: Hot-cold chambers are used for simulating heating, freezing, and thawing cycles to evaluate the impact of temperature variations on food products, packaging materials, and storage equipment, ensuring the safety and quality of food throughout its lifecycle.

Features

1. Rapid Transition: These chambers enable rapid transitions between temperature extremes, with ramp rates of up to 10°C/min.

2. Precise Temperature Control: Hot-cold chambers provide precise temperature control.

3. Programmable Temperature Profiles: These chambers allow users to program temperature profiles and dwell times according to specific testing requirements.

4. Humidity Control: as a option if needed

5. Viewing Window, Interior Light as standard configuration.

6. The user-friendly interface makes it easy to input desired temperature settings and control the chamber's operation

7. Overtemperature Protection: To ensure safety during testing, hot-cold chambers incorporate overtemperature protection mechanisms.

Quality and Safety

All our Hot Cold Chamber comply with international quality and safety directives. The manufacturing facility is ISO 9001 certified for strict quality control. The chambers meet CE guidelines and are EMC compliant for product safety. Regular safety testing ensures protection against electrical, mechanical and thermal hazards.