constant temperature chamber

Lowest Temperature: -20℃/-40℃/-60℃/-80℃;

Temperature Range:-20℃~+150 ℃;

Humidity Range:20% ~ 98% RH;

Refrigerant: Environmental refrigerant;

Temperature and Humidity condition

Touch-screen programmble controller,Ethernet access

- Product Description

Constant temperature chamber Manufacturer & Supplier

The constant temperature chamber is an advanced climate simulation device designed to recreate and maintain a stable temperature environment for testing purposes. With capacities ranging from 100L to 1000L, LIB industry's temperature controlled chambers provide precise temperature control across a wide range from -70°C to +180°C.

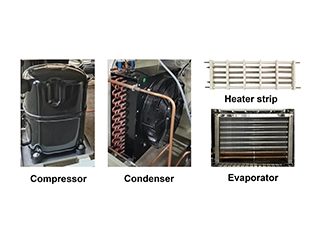

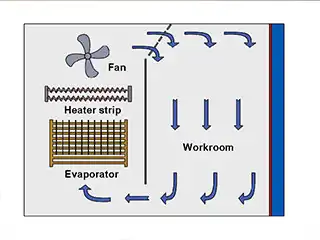

The main components include the insulated test space, refrigeration system, heating system, airflow circulation, humidity control, and a microprocessor controller. Temperature is precisely regulated via advanced PID control to maintain stability even with frequent door openings. The insulated chamber walls minimize heat loss for high thermal efficiency. Forced air circulation ensures uniform test conditions throughout the chamber. Optional humidity control allows combined temperature and humidity testing.

Product Parameter

Model | T-100 | T-225 | T-500 | T-800 | T-1000 |

Internal Dimension (mm) | 400*500*500 | 500*600*750 | 700*800*900 | 800*1000*1000 | 1000*1000*1000 |

Overall Dimension (mm) | 900*1050*1620 | 1000*1140*1870 | 1200*1340*2020 | 1300*1540*2120 | 1500*1540*2140 |

Interior Volume | 100L | 225L | 500L | 800L | 1000L |

Heat load | 1000W | ||||

Temperature Range | A : -20℃ ~ +150 ℃ B : -40℃ ~ +150 ℃ C: -70℃ ~ +150 ℃ | ||||

Temperature Fluctuation | ± 0.5 ℃ | ||||

Temperature Deviation | ± 2.0 ℃ | ||||

Cooling Rate | 3 ℃ / min | ||||

Heating Rate | 1 ℃ / min | ||||

Cooling system | Mechanical compression refrigeration system | ||||

Refrigerating unit | French TECUMSEH compressor | ||||

Heating Element | Nichrome heater | ||||

Controller | Programmable color LCD touch screen controller Ethernet connection, PC Link | ||||

Temperature Sensor | PTR Platinum Resistance PT100Ω/MV A-class | ||||

Air Circulation | Centrifugal wind fan | ||||

Safety Device | Over-temperature Protection; Over-current Protection; Refrigerant High-Pressure Protection; Earth leakage Protection | ||||

Exterior Material | Steel Plate with protective coating | ||||

Interior Material | SUS304 stainless steel | ||||

Thermal Insulation | Polyurethane foam and insulation cotton | ||||

Observation Window | Interior lighting, double-layer thermo stability silicone rubber sealing | ||||

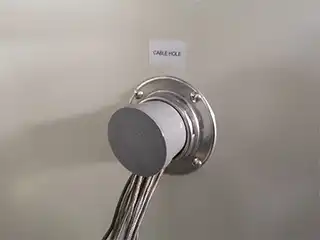

Standard Configuration | 1 Cable hole (Φ 50,) with plug; 2 shelves | ||||

Product Details

|

|

|

Cable hole The standard inner hole diameter is 50mm/100mm/200mm Soft silicone plug seal; Metal enclosure closed | Cooling system Mechanical compression refrigeration system French TECUMSEH compressor Environmentally friendly refrigerant | Air circulation The air is uniformly distributed through the air outlet Air circulates evenly throughout the workroom |

|

|

Constant temperature chamber Key Features

Precise temperature control from -70°C to +180°C: PID control system allows accurate and stable temperature regulation across a wide range.

Excellent thermal uniformity +/-0.5°C: Forced air circulation by fans ensures uniformity within ±0.5°C throughout the chamber.

Intuitive touchscreen controller: User-friendly controller with graphic display allows easy setpoint entry and programming of temperature profiles.

Programmable temperature profiles: Flexible programming of ramp rates, soak temperatures and dwell times to simulate real-world conditions.

Overtemperature protection for safety: Independent thermostats, temperature limiters and low liquid level cutoff provide protection against overheating.

Interior lighting and viewing window: Interior LED lighting and optional glass window allow observation of test items without disruption.

Compact, space-saving design: Smaller footprint saves precious laboratory floor space.

Low noise operation < 65 dBA: Quiet operation suitable for laboratory environments.

Durable stainless-steel interior: Stainless steel inner chamber resists corrosion and contamination during testing.

Data acquisition interfaces: USB ports, Ethernet, and data logger for test data monitoring, recording and analysis.

Safety certification: Temperature Chamber comply with CE and other certifications for electrical, mechanical and thermal safety.

Quality and Certification

LIB industry constant temperature chambers comply with international quality standards and safety regulations:

ISO 9001 certified manufacturing facility

CE marked construction for safety

EMC compliance for electromagnetic compatibility

ISO17025 Calibration

Industry-specific certifications on request

Customization

We offer customization of Temperature Chamber as per specific test requirements:

Custom temperature ranges and ramp rates

Integrated humidity and other environmental controls

Casters and shelves for material handling

Data acquisition and communication interfaces

Custom paint